Linear Motion Rolling Guides Linear Roller Way Super X Series

Linear Motion Rolling Guides Linear Roller Way Super X Series

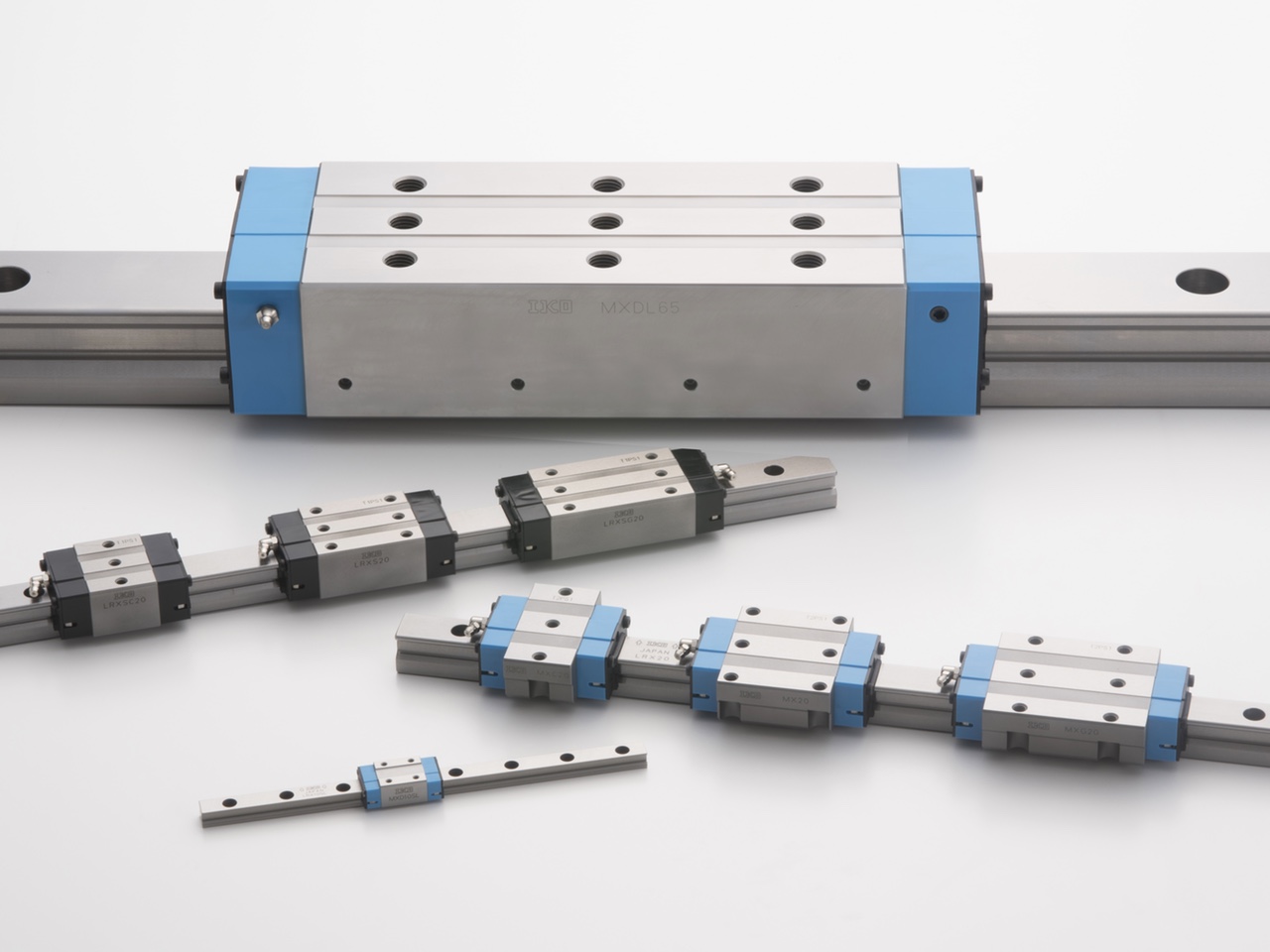

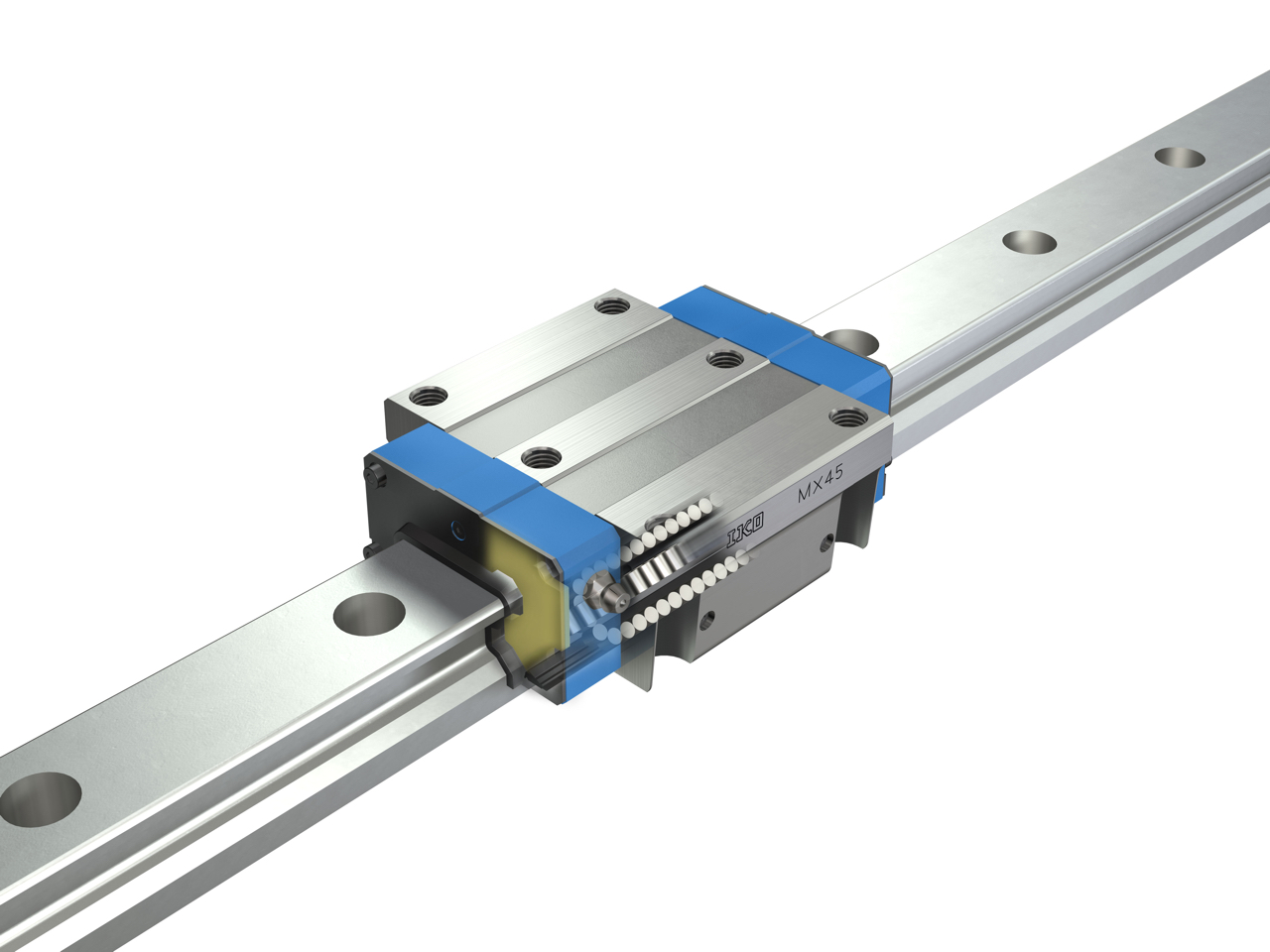

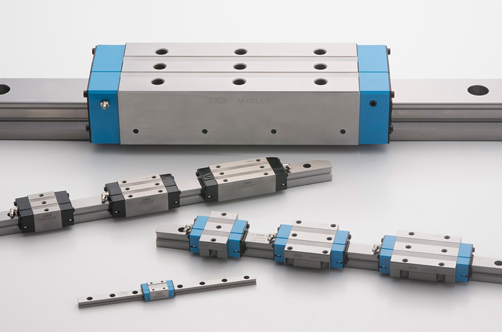

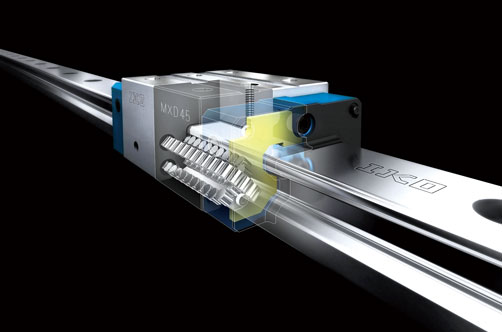

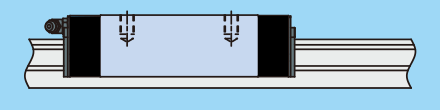

IKO Linear Roller Way Super X is a high-performance roller type linear motion rolling guide with 4 rows of well-balanced cylindrical rollers arranged in parallel in a high-rigidity casing. This allows for smooth running, high reliability, stable high accuracy and rigidity. Even when heavy load or fluctuating load is applied, it has low elastic deformation and is stable, making it suitable when vibration or shock is applied. Models are available in a wide range of performances and sizes, and can be selected according to the application.

C-Lube Linear Roller Way Super MX

C-Lube Linear Roller Way Super MX incorporates C-Lube lubrication into the Linear Roller Way Super X. The same high performance can be achieved for applications requiring high load capacity and running accuracy such as machine tools and semiconductor/liquid crystal related manufacturing equipment, but with C-Lube, long-term, maintenance-free performance can also be realized. This reduces the cost of the whole system by reducing the running costs and the work hours required for lubrication.

Maintenance-Free

Our C-Lube technology maintains the lubrication performance for an extended period of time, reducing lubrication schedules and the time it takes to manage them.

Linear Roller Way Super X

Interchangeable

Interchange specifications are available. Since the slide unit and track rail dimensions are separate, each can be individually added or exchanged.

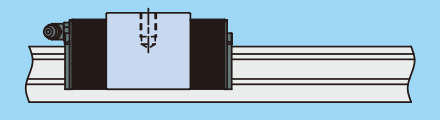

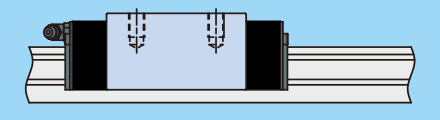

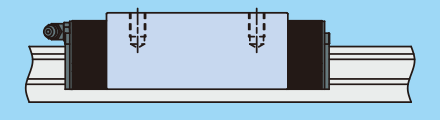

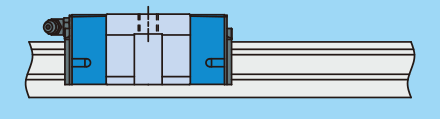

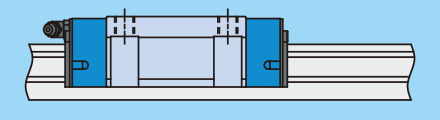

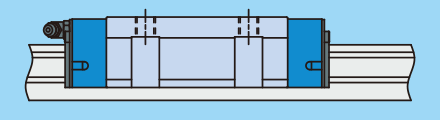

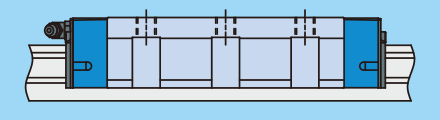

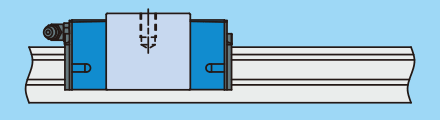

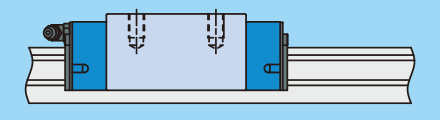

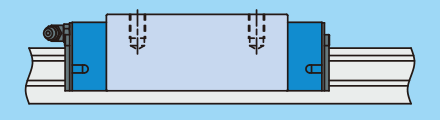

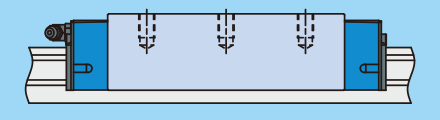

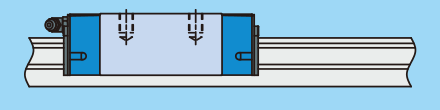

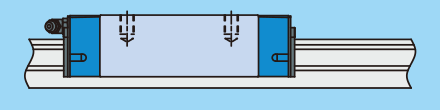

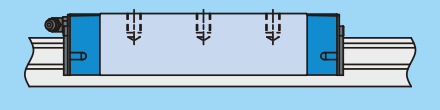

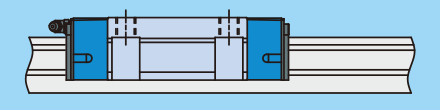

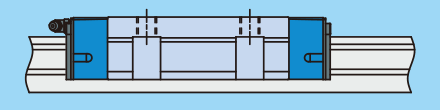

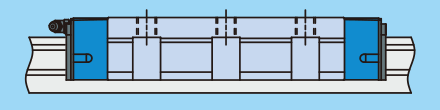

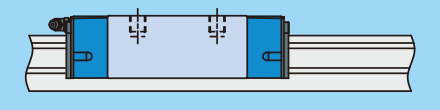

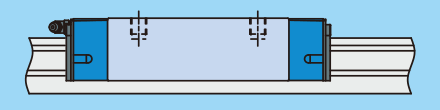

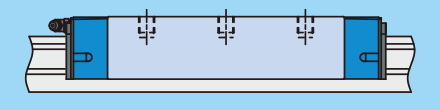

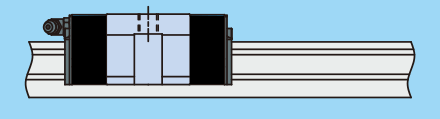

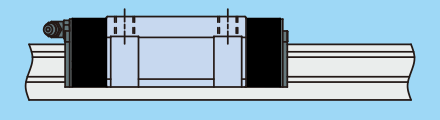

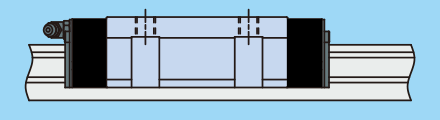

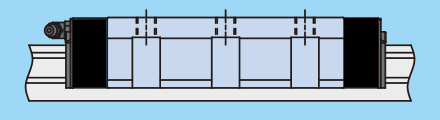

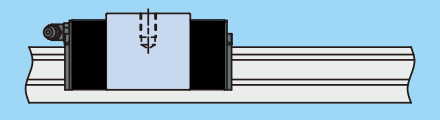

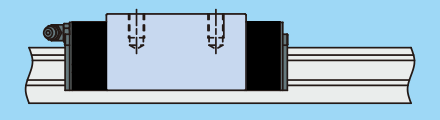

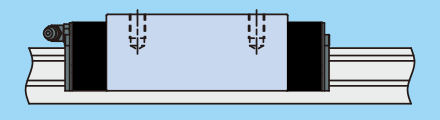

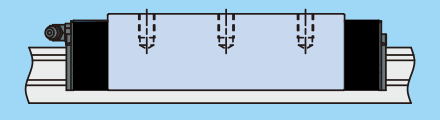

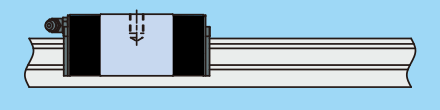

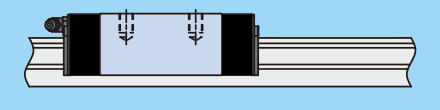

Length of Slide Unit

Four types with the same cross-sectional dimensions but different slide unit lengths are available: short type, standard type, long type and extra-long type. Each can be selected according to the application.

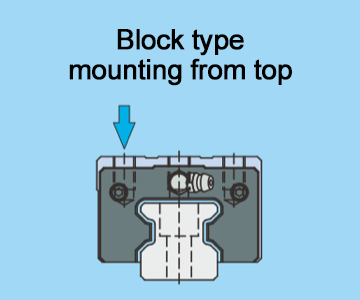

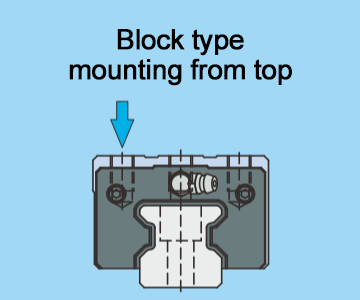

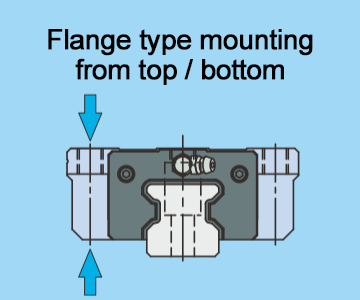

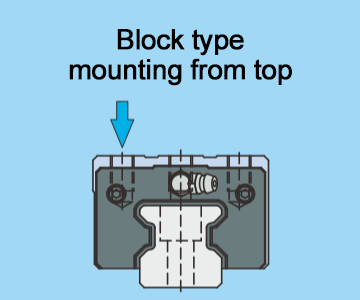

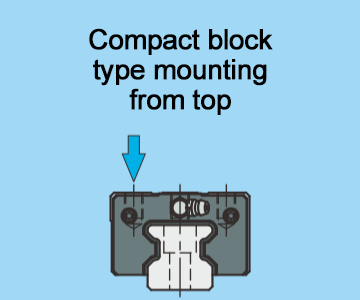

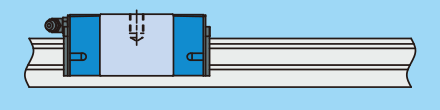

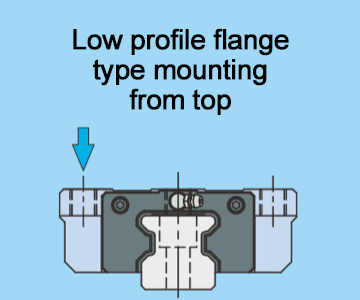

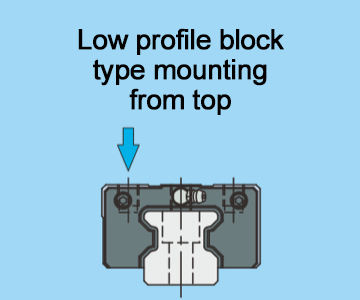

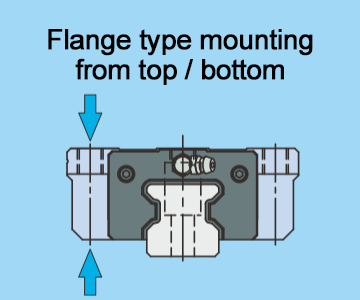

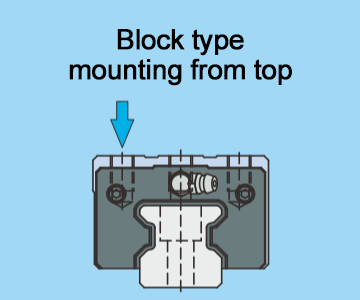

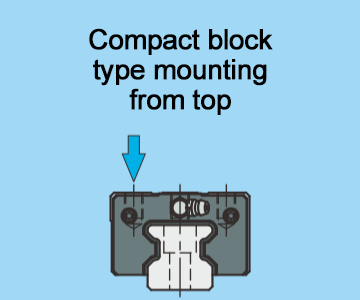

Flange Type and Block Type

Slide unit shapes include a flange type that can be mounted from either the top or bottom, and a narrow block type.

Dimensional Compatibility with Ball Type

Since the mounting dimensions are the same as the ball type Linear Way H, it is easy to include in the specifications of machines and equipment.

Stainless Steel

Stainless steel types, with excellent corrosion resistance, are also available. They are ideal for use in clean rooms for medical equipment, various disc readers and semiconductor manufacturing devices.

Line-Up

C-Lube Linear Roller Way Super MX ・ Linear Roller Way Super X - Stainless Steel

| Product | Shape | Slide unit Length | Mode | Size | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 12 | 15 | 20 | 25 | 30 | 35 | 45 | 55 | 65 | 85 | 100 | ||||

| C-Lube Linear Roller Way Super MX |

|

|

MXD…SL | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | - |

| Linear Roller Way Super X |

|

|

LRXDC…SL | - | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | - |

|

LRXD…SL | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | - | ||

|

LRXDG…SL | - | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | - | ||

*For the models indicated in , the interchangeable specification is available.

C-Lube Linear Roller Way Super MX・Linear Roller Way Super X - High carbon Steel

| Product | Shape | Slide unit Length | Mode | Size | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 12 | 15 | 20 | 25 | 30 | 35 | 45 | 55 | 65 | 85 | 100 | ||||

| C-Lube Linear Roller Way Super MX |

|

|

MXC | - | ○ | ○ | ○(1) | ○ | ○ | ○ | ○ | ○ | ○ | - | - |

|

MX | - | ○ | ○ | ○(1) | ○ | ○ | ○ | ○ | ○ | ○ | - | - | ||

|

MXG | - | ○ | ○ | ○(1) | ○ | ○ | ○ | ○ | ○ | ○ | - | - | ||

|

MXL | - | - | - | ○(1) | ○ | ○ | ○ | ○ | ○ | ○ | - | - | ||

| C-Lube Linear Roller Way Super MX |

|

|

MXDC | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - |

|

MXD | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | ||

|

MXDG | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | ||

|

MXDL | - | - | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | ||

| C-Lube Linear Roller Way Super MX |

|

|

MXSC | - | - | ○ | ○ | ○ | ○ | - | - | - | - | - | - |

|

MXS | - | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | ||

|

MXSG | - | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | ||

|

MXSL | - | - | - | ○ | ○ | ○ | - | - | - | - | - | - | ||

| C-Lube Linear Roller Way Super MX |

|

|

MXN | - | - | - | - | - | ○ | ○ | ○ | ○ | - | - | - |

|

MXNG | - | - | - | - | - | ○ | ○ | ○ | ○ | - | - | - | ||

|

MXNL | - | - | - | - | - | ○ | ○ | ○ | ○ | - | - | - | ||

| C-Lube Linear Roller Way Super MX |

|

|

MXNS | - | - | - | - | - | ○ | ○ | ○ | ○ | - | - | - |

|

MXNSG | - | - | - | - | - | ○ | ○ | ○ | ○ | - | - | - | ||

|

MXNSL | - | - | - | - | - | ○ | ○ | ○ | ○ | - | - | - | ||

| Linear Roller Way Super X |

|

|

LRXC | - | ○ | ○ | ○(1) | ○ | ○ | ○ | ○ | ○ | ○ | - | - |

|

LRX | - | ○ | ○ | ○(1) | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | ||

|

LRXG | - | ○ | ○ | ○(1) | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||

|

LRXL | - | - | - | - | - | - | - | - | - | - | ○ | - | ||

| Linear Roller Way Super X |

|

|

LRXDC | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - |

|

LRXD | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | ||

|

LRXDG | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | ||

|

LRXDL | - | - | - | - | - | - | - | - | - | - | ○ | - | ||

| Linear Roller Way Super X |

|

|

LRXSC | - | - | ○ | ○ | ○ | ○ | - | - | - | - | - | - |

|

LRXS | - | - | ○ | ○ | ○ | ○ | - | - | - | - | - | - | ||

|

LRXSG | - | - | ○ | ○ | ○ | ○ | - | - | - | - | - | - | ||

*For the models indicated in , the interchangeable specification is available.

Note (1) MXC20, MX20, MXG20, MXL20, LRXC20, LRX20 and LRXG20 can only be mounted by the bolts from top.

The models with the same dimensions allowing mounting from bottom are MXHC20, MXH20, MXHG20, MXHL20, LRXHC20, LRXH20

and LRXHG20.

Special Specification

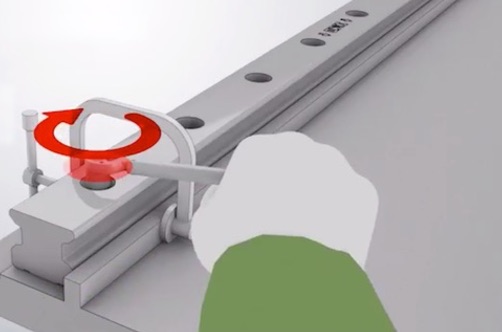

Caps for rail mounting holes

Dedicated caps for rail mounting holes are included. They close track rail mounting holes to improve sealing property in a motion direction. Contact IKO for aluminum alloy caps for rail mounting holes.

Rail cover plate for track rail

Deliver with the track rail cover plate mounted. Covering the upper surface with U-shape stainless steel thin plate after assembly of the track rail improves the sealing property further. Change the end seal to dedicated one.

Double end seals

Double end seals are mounted to the slide unit to improve dust prevention.

Scraper

A metal scraper is mounted to the slide unit. The scraper is non-contact type and effectively eliminates large foreign substances adhering to the track rail.

Female threads for bellows

Female threads for bellows are prepared on the slide unit and track rail ends.

Inner seal

Attach the inner seal to the inside of the slide unit.

C-Wiper

C-Wiper is mounted on the slide unit end to improve dust protection property.

With C-Lube plate

The C-Lube impregnated with lubricant is attached inside the end seal of the slide unit, so that the interval for reapplicating lubricant can be extended.

Black chrome surface treatment

Acrylate resin coating is applied to improve the rust prevention property after black impregnated chrome surface treatment.

Fluorine black chrome surface treatment

Fluorinated resin coating is applied to improve the rust prevention property after black impregnated chrome surface treatment. In addition, this prevent foreign substances from sticking to the surface.