Linear Motion Rolling Guides Linear Way F

Linear Motion Rolling Guides Linear Way F

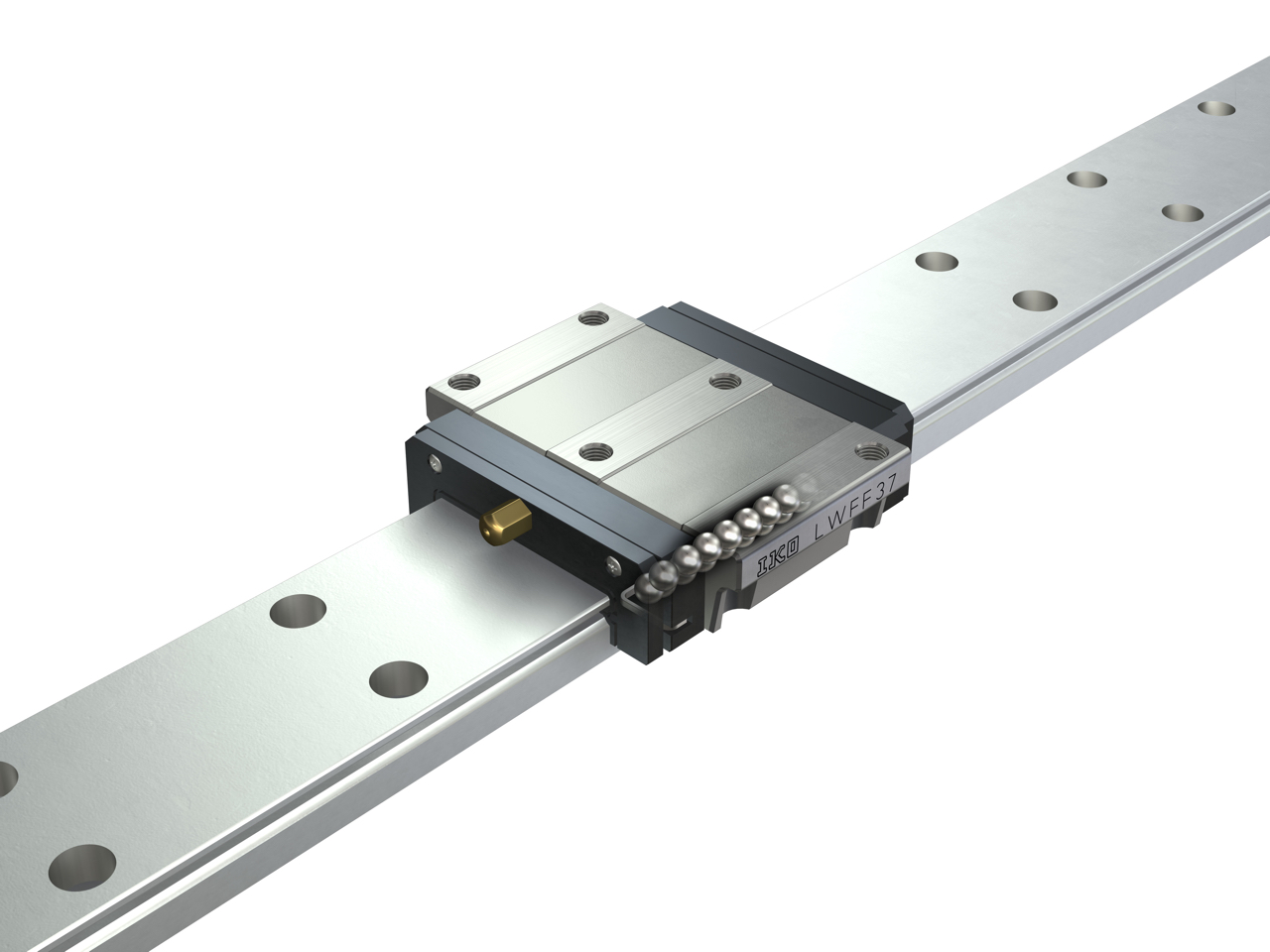

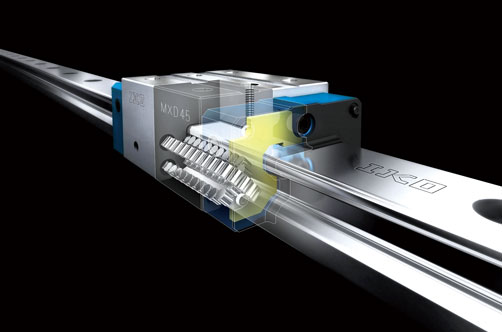

IKO Linear Way F is a linear motion rolling guide with a highly rigid slide unit that performs endless linear motion over a wide track rail. Two rows of steel balls contact the raceway at four points with a high number of load-bearing balls. This enables stable high accuracy and rigidity even in applications where load has variable direction and size or complex load is applied. Since it is wide, it is also resistant to moment load in the width direction, so it is suitable for single row use as well.

Product Features

Wide Structure

Since the distance between moment load points is long, it is resistant to moment loads and complex loads.

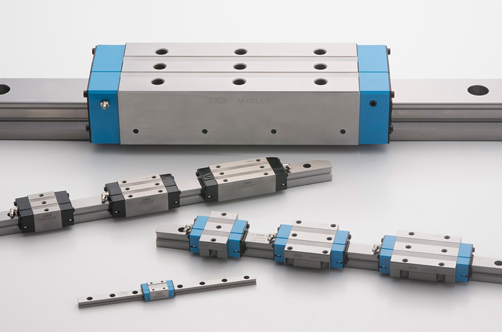

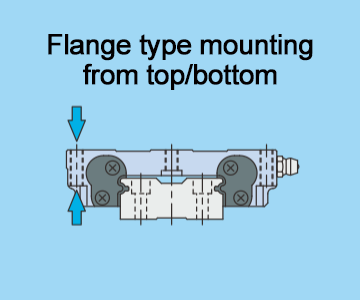

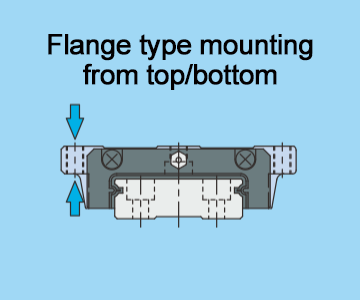

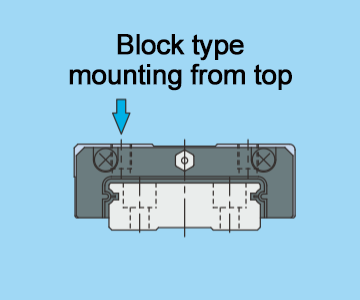

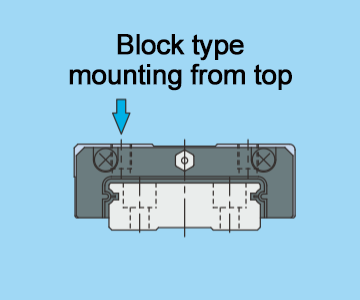

Flange Type and Block Type

Slide units include two flange types from different dimensional series, and three narrow block types.

Stainless Steel

Stainless steel types, with excellent corrosion resistance, are also available. They are ideal for use in clean rooms for medical equipment, various disc readers and semiconductor manufacturing devices.

Interchangeable

Interchange specifications are available. Since the slide unit and track rail dimensions are separate, each can be individually added or exchanged.

Excellent Load Balance

The two-row simple structure utilizes large-diameter steel balls that provide high load rating, enabling balanced loading in all directions.

High Rigidity

Since the steel balls contact the rigid casing at four points, their restraint is excellent and high rigidity can be obtained in all directions.

Line-Up

Linear Way F

| Product | Material | Shape | Model | Size | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 33 | 37 | 40 | 42 | 60 | 69 | 90 | ||||

| Linear Way F | High Carbon Steel |

|

LWFH | - | - | ○ | - | ○ | - | ○ |

| Linear Way F |

|

LWFF | ○ | ○ | - | ○ | - | ○ | - | |

| Linear Way F |

|

LWFS | ○ | ○ | - | - | - | - | - | |

| Linear Way F | Stainless steel made |

|

LWFS…SL | ○ | ○ | - | ○ | - | - | - |

*For the models indicated with the interchangeable specification is available.

Special Specifications

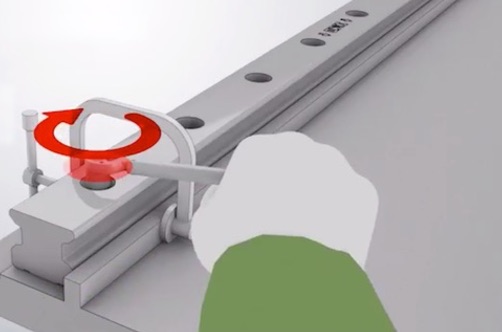

Caps for rail mounting holes

Dedicated caps for rail mounting holes are included. They close track rail mounting holes to improve sealing property in a motion direction. Contact IKO for aluminum alloy caps for rail mounting holes.

Double end seals

Double end seals are mounted to the slide unit to improve dust prevention.

Scraper

A metal scraper is mounted to the slide unit. The scraper is non-contact type and effectively eliminates large foreign substances adhering to the track rail.

Female threads for bellows

Female threads for bellows are prepared on the slide unit and track rail ends.

Black chrome surface treatment

Acrylate resin coating is applied to improve the rust prevention property after black impregnated chrome surface treatment.

Fluorine black chrome surface treatment

Fluorinated resin coating is applied to improve the rust prevention property after black impregnated chrome surface treatment. In addition, this prevents foreign substances from sticking to the surface.

Under seal

The seal is attached to the bottom of the slide unit to prevent foreign substances from entering from underneath.

With C-Lube plate

The C-Lube impregnated with lubricant is attached inside the end seal of the slide unit, so that the interval for reapplicating lubricant can be extended.