Linear Motion Rolling Guides Linear Way E Series

Linear Motion Rolling Guides Linear Way E Series

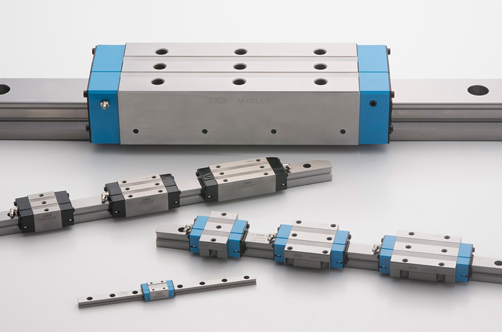

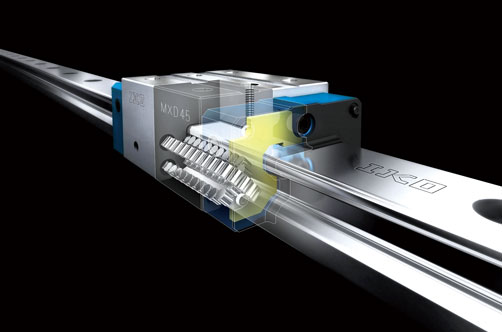

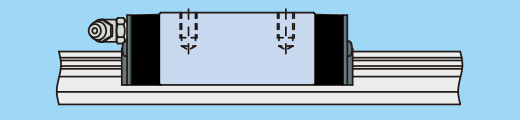

Linear Way E is a linear motion rolling guide with a compact slide unit that provides endless linear motion over a track rail. Two rows of steel balls come in contact with the raceway surface at four points, enabling stable accuracy and rigidity, even in applications where loads have variable direction and size, or complex loads are applied. This compact, highly versatile universal series is available in many shapes and sizes.

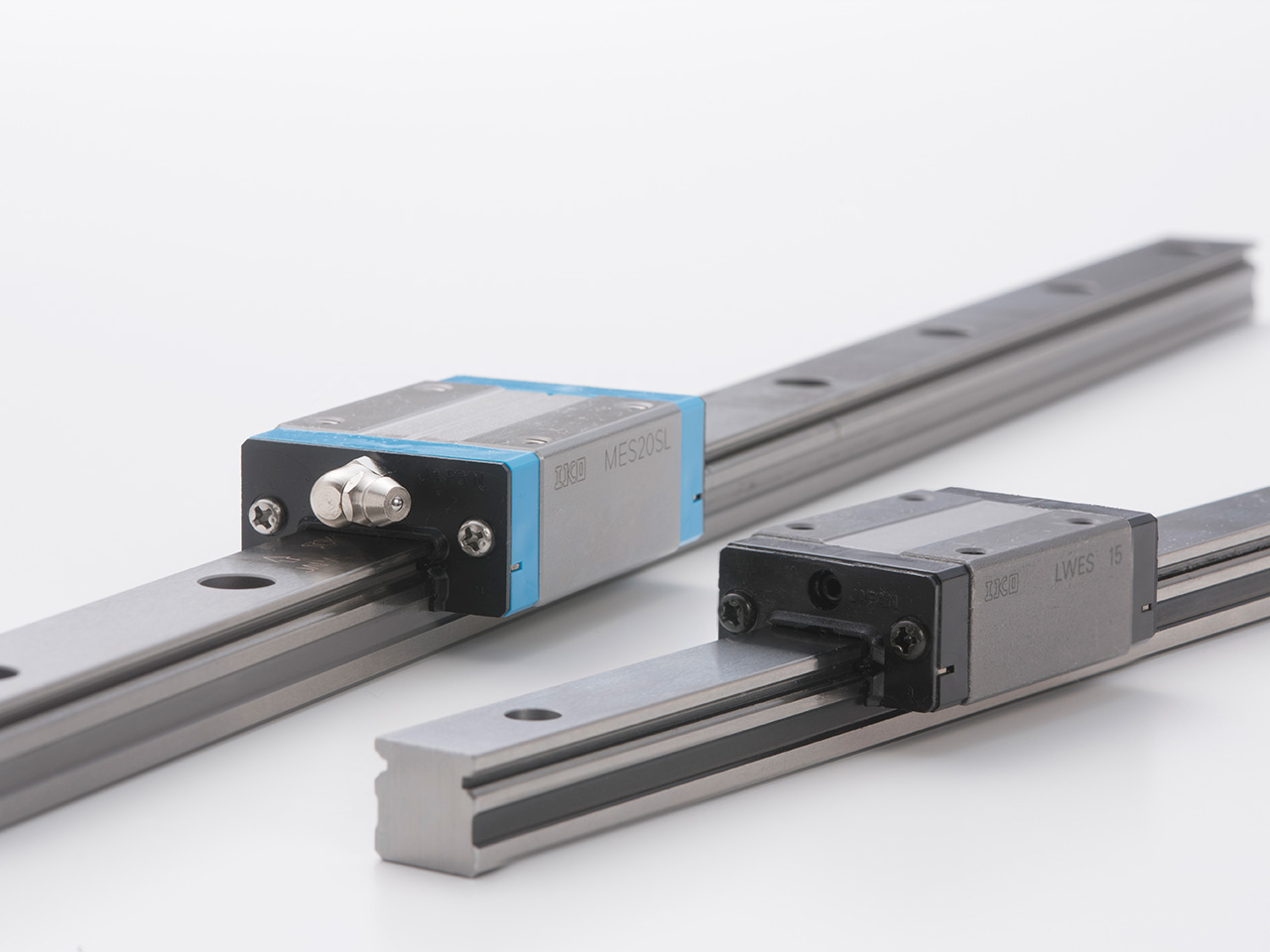

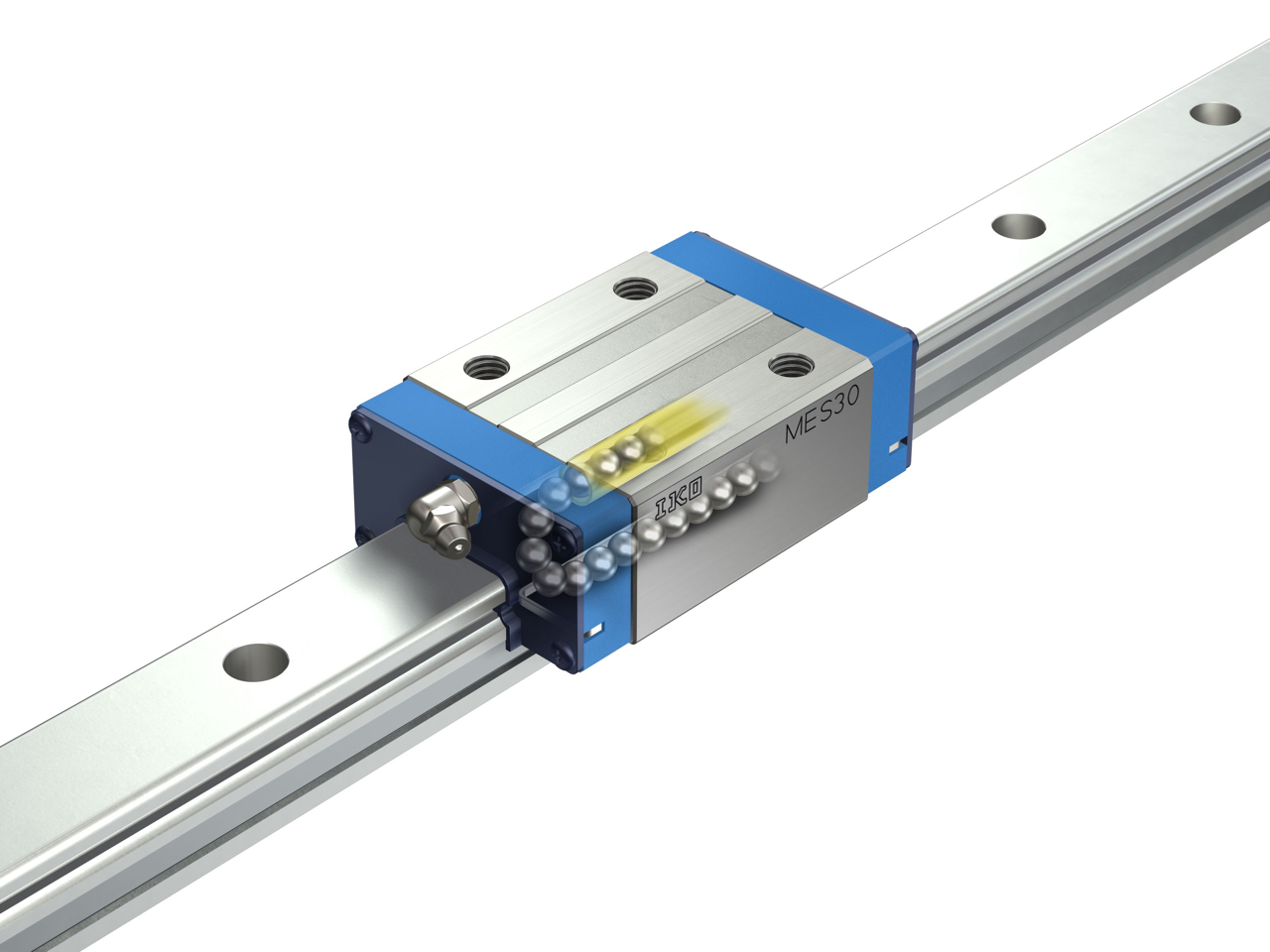

C-Lube Linear Way ME

C-Lube Linear Way ME is an E-Series linear motion rolling guide with built-in C-Lube lubrication that provides long-term, maintenance-free operation.

Maintenance-Free

Our C-Lube technology maintains the lubrication performance for an extended period of time, reducing lubrication schedules and the time it takes to manage them.

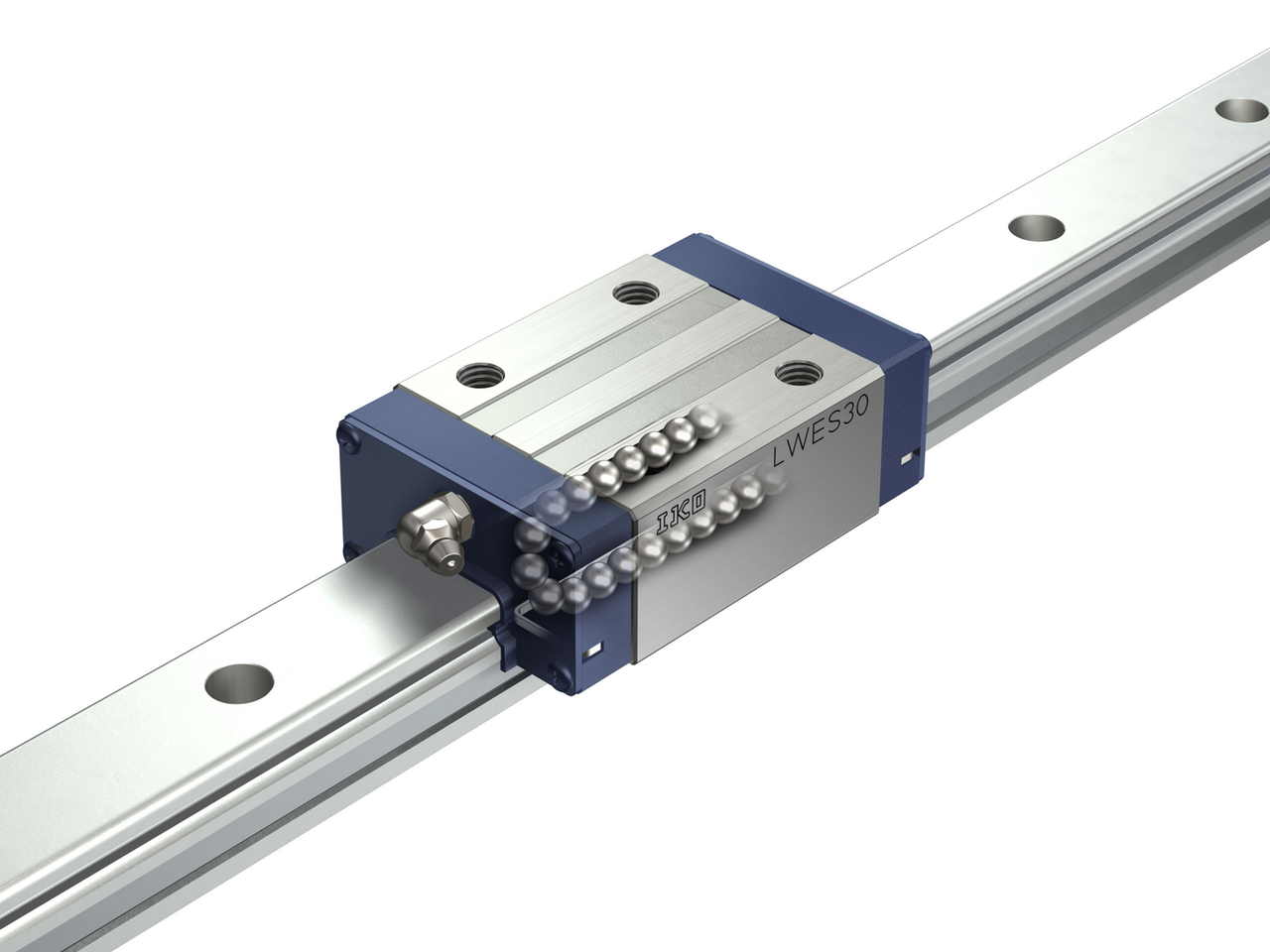

Linear Way E

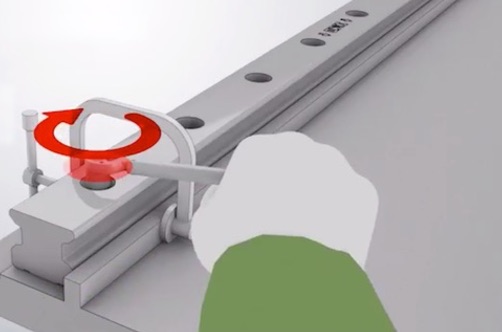

Interchangeable

Interchange specifications are available. Since the slide unit and track rail dimensions are separate, each can be individually added or exchanged.

Compact Design

Lower, narrower, shorter...more compact in every aspect.

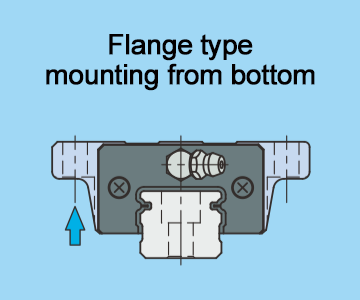

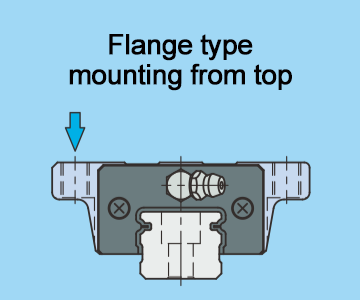

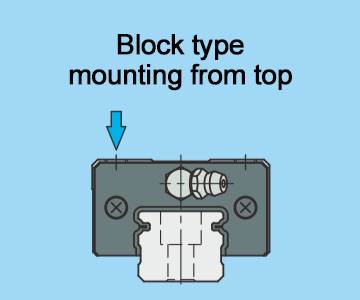

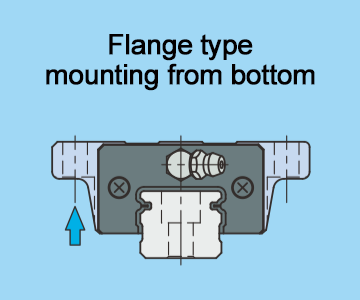

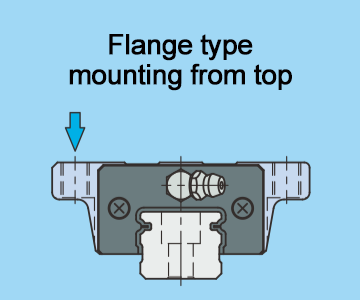

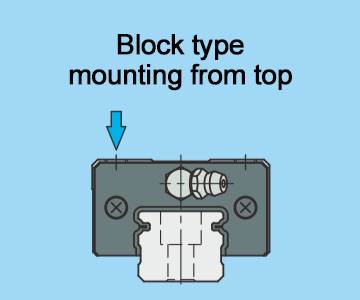

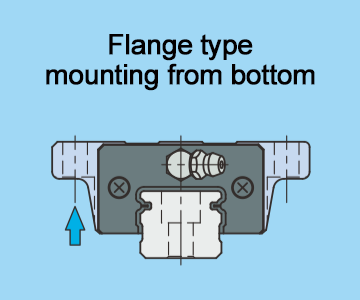

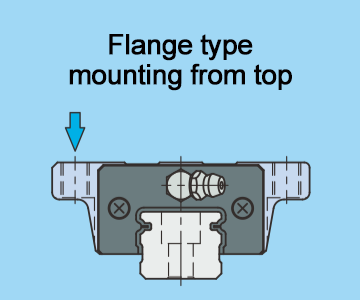

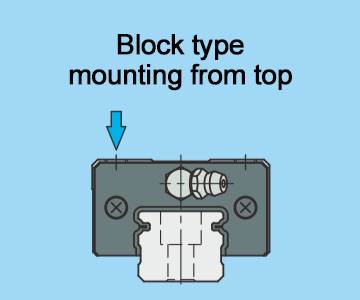

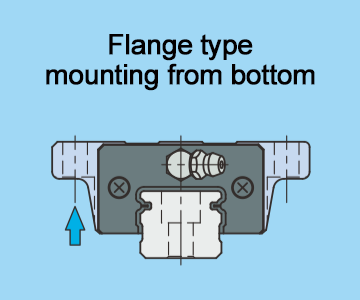

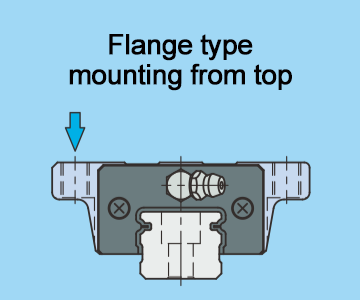

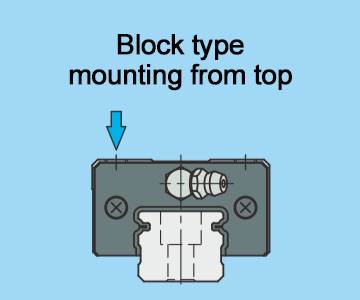

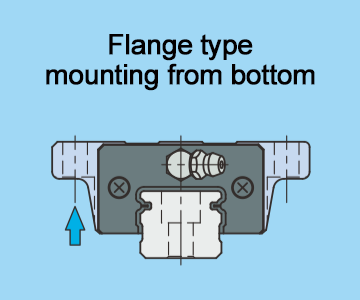

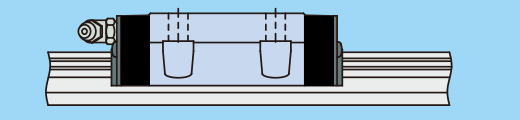

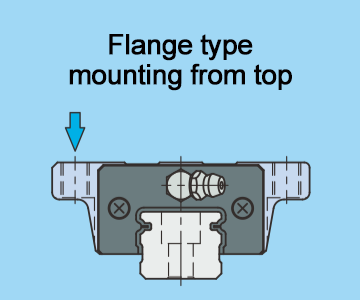

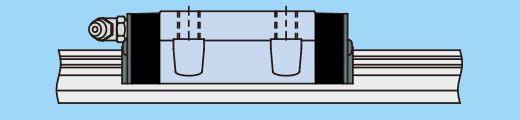

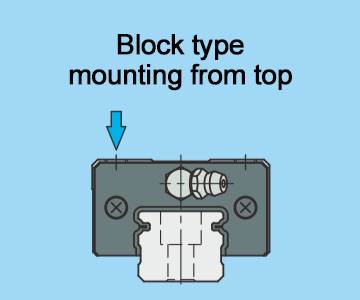

Flange Type and Block Type

Slide units include two flange types with different mounting directions and three narrow block types.

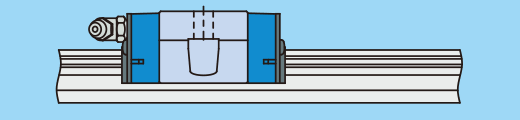

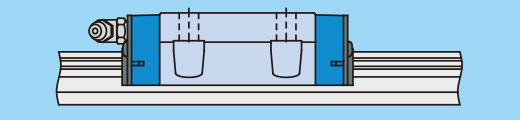

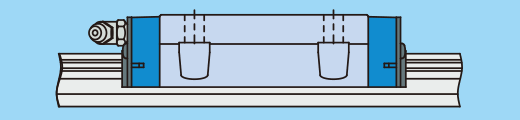

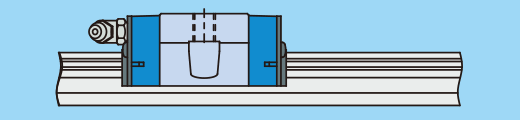

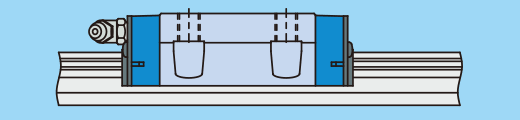

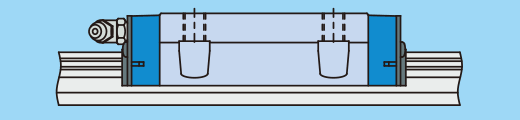

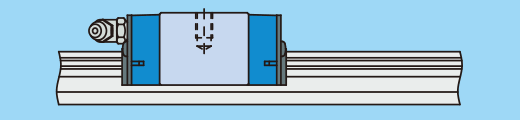

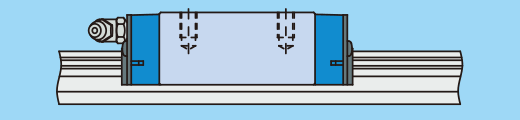

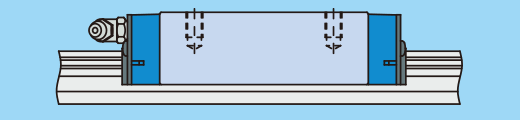

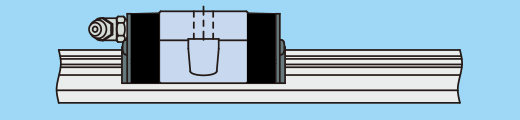

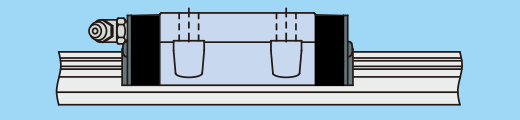

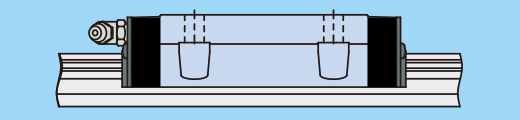

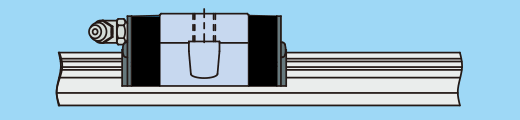

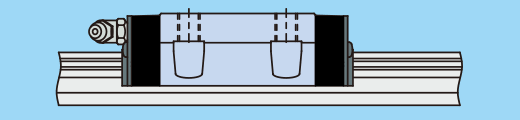

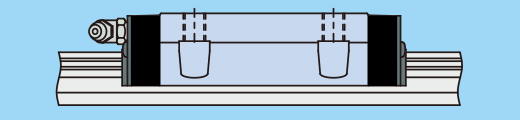

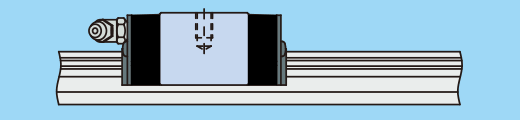

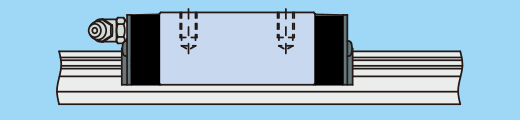

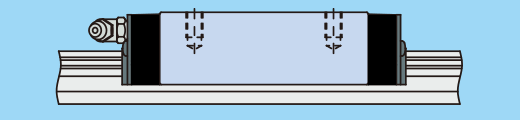

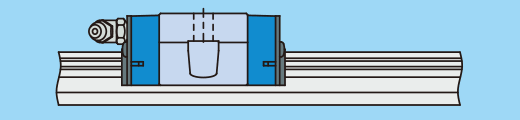

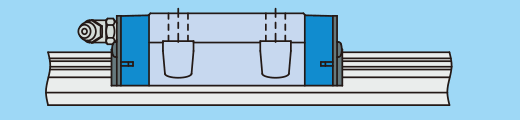

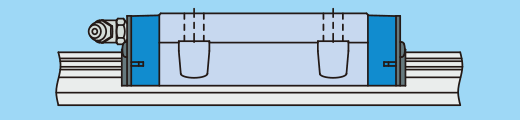

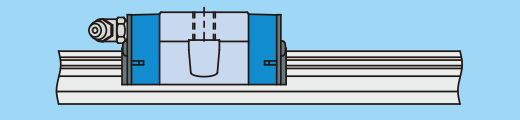

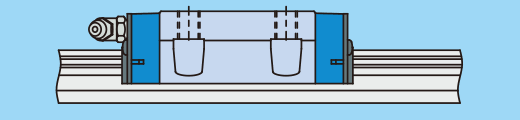

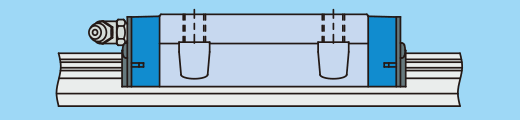

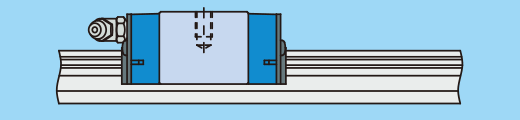

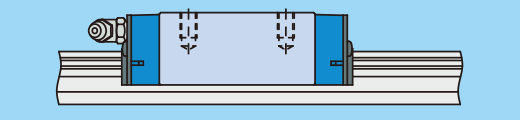

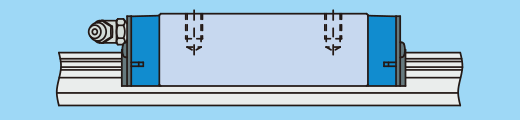

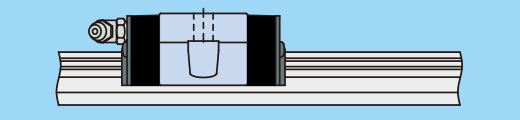

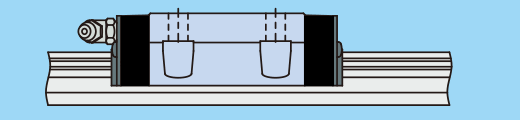

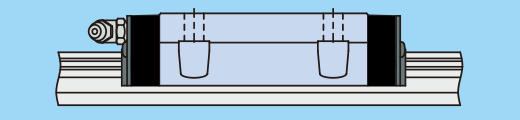

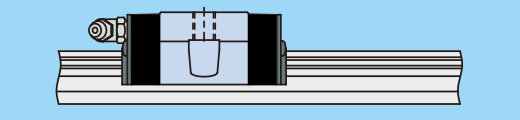

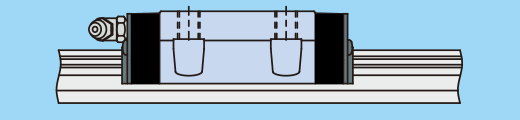

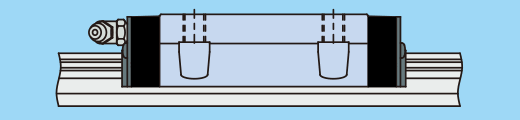

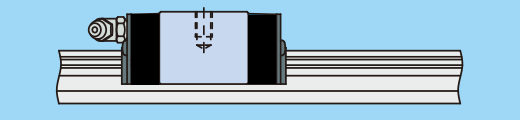

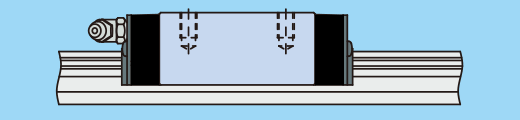

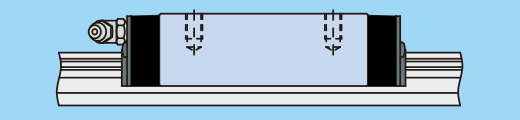

Length of Slide Unit

Available types include: a short type, with the same cross-section as the standard type, and a high-rigidity long type.

Stainless Steel

Stainless steel types, with excellent corrosion resistance, are also available. They are ideal for use in clean rooms for medical equipment, various disc readers and semiconductor manufacturing devices.

Low Decibel Linear Way E

The Low Decibel Linear Way E is a linear motion rolling guide optimally designed based on thorough analysis of steel ball re-circulation behavior and sound quality analysis. Due to a resin separator built-in between the balls, direct contact is eliminated and smooth and quiet motion is achieved. Especially in manufacturing machinery that uses several linear motion rolling guides, they can reduce the noise level in the factory, contributing to a better work environment for the employees.

Low Noise

By incorporating a resin separator that prevents direct contact between the steel balls, smooth and quiet motion is realized. When used in manufacturing machinery that uses several linear motion rolling guides, they can reduce the noise level in the factory and provide a better work environment for the employees.

Dimensional Compatibility with Linear Way E

Since the mounting dimensions are the same as Linear Way E, it can be replaced without changing the design of the machine or device.

Line-Up

C-Lube Linear Way ME・Linear Way E - Stainless Steel

| Product | Shape | Slide unit Length | Model | Size | |||||

|---|---|---|---|---|---|---|---|---|---|

| 15 | 20 | 25 | 30 | 35 | 45 | ||||

| C-Lube Linear Way ME |

|

|

MEC…SL | ○ | ○ | ○ | ○ | - | - |

|

ME…SL | ○ | ○ | ○ | ○ | - | - | ||

|

MEG…SL | ○ | ○ | ○ | ○ | - | - | ||

| C-Lube Linear Way ME |

|

|

METC…SL | ○ | ○ | ○ | ○ | - | - |

|

MET…SL | ○ | ○ | ○ | ○ | - | - | ||

|

METG…SL | ○ | ○ | ○ | ○ | - | - | ||

| C-Lube Linear Way ME |

|

|

MESC…SL | ○ | ○ | ○ | ○ | - | - |

|

MES…SL | ○ | ○ | ○ | ○ | - | - | ||

|

MESG…SL | ○ | ○ | ○ | ○ | - | - | ||

| Linear Way E |

|

|

LWEC…SL | ○ | ○ | ○ | ○ | - | - |

|

LWE…SL | ○ | ○ | ○ | ○ | - | - | ||

|

LWEG…SL | ○ | ○ | ○ | ○ | - | - | ||

| Linear Way E |

|

|

LWETC…SL | ○ | ○ | ○ | ○ | - | - |

|

LWET…SL | ○ | ○ | ○ | ○ | - | - | ||

|

LWETG…SL | ○ | ○ | ○ | ○ | - | - | ||

| Linear Way E |

|

|

LWESC…SL | ○ | ○ | ○ | ○ | - | - |

|

LWES…SL | ○ | ○ | ○ | ○ | - | - | ||

|

LWESG…SL | ○ | ○ | ○ | ○ | - | - | ||

For the models indicated in , the interchangeable specification is available.

C-Lube Linear Way ME・Linear Way E - High Carbon Steel

| Product | Slide unit Shape | Slide unit Length | Model | Size | |||||

|---|---|---|---|---|---|---|---|---|---|

| 15 | 20 | 25 | 30 | 35 | 45 | ||||

| C-Lube Linear Way ME |

|

|

MEC | ○ | ○ | ○ | ○ | ○ | - |

|

ME | ○ | ○ | ○ | ○ | ○ | ○ | ||

|

MEG | ○ | ○ | ○ | ○ | - | - | ||

| C-Lube Linear Way ME |

|

|

METC | ○ | ○ | ○ | ○ | ○ | - |

|

MET | ○ | ○ | ○ | ○ | ○ | ○ | ||

|

METG | ○ | ○ | ○ | ○ | - | - | ||

| C-Lube Linear Way ME |

|

|

MESC | ○ | ○ | ○ | ○ | ○ | - |

|

MES | ○ | ○ | ○ | ○ | ○ | ○ | ||

|

MESG | ○ | ○ | ○ | ○ | - | - | ||

| Linear Way E |

|

|

LWEC | ○ | ○ | ○ | ○ | ○ | - |

|

LWE | ○ | ○ | ○ | ○ | ○ | ○ | ||

|

LWEG | ○ | ○ | ○ | ○ | - | - | ||

| Linear Way E |

|

|

LWETC | ○ | ○ | ○ | ○ | ○ | - |

|

LWET | ○ | ○ | ○ | ○ | ○ | ○ | ||

|

LWETG | ○ | ○ | ○ | ○ | - | - | ||

| Linear Way E |

|

|

LWESC | ○ | ○ | ○ | ○ | ○ | - |

|

LWES | ○ | ○ | ○ | ○ | ○ | ○ | ||

|

LWESG | ○ | ○ | ○ | ○ | - | - | ||

For the models indicated in , the interchangeable specification is available.

Low Decibel Linear Way E - High Carbon Steel

| Product | Slide unit Shape | Slide unit Length | Model | Size | |||||

|---|---|---|---|---|---|---|---|---|---|

| 15 | 20 | 25 | 30 | 35 | 45 | ||||

| Low Decibel Linear Way |

|

|

LWE…Q | ○ | ○ | ○ | ○ | ○ | - |

| Low Decibel Linear Way |

|

|

LWET…Q | ○ | ○ | ○ | ○ | ○ | - |

| Low Decibel Linear Way |

|

|

LWES…Q | ○ | ○ | ○ | ○ | ○ | - |

Special Specifications

Caps for rail mounting holes

Dedicated caps for rail mounting holes are included. They close track rail mounting holes to improve sealing property in a motion direction. Contact IKO for aluminum alloy caps for rail mounting holes.

Double end seals

Double end seals are mounted to the slide unit to improve dust prevention.

Scraper

A metal scraper is mounted to the slide unit. The scraper is non-contact type and effectively eliminates large foreign substances adhering to the track rail.

Female threads for bellows

Female threads for bellows are prepared on the slide unit and track rail ends.

Black chrome surface treatment

Acrylate resin coating is applied to improve the rust prevention property after black impregnated chrome surface treatment.

Fluorine black chrome surface treatment

Fluorinated resin coating is applied to improve the rust prevention property after black impregnated chrome surface treatment. In addition, this prevent foreign substances from sticking to the surface.

Under seal

The seal is attached to the bottom of the slide unit to prevent foreign substances from entering from underneath.

With C-Lube Plate

The C-Lube impregnated with lubricant is attached inside the end seal of the slide unit, so that the interval for reapplicating lubricant can be extended.