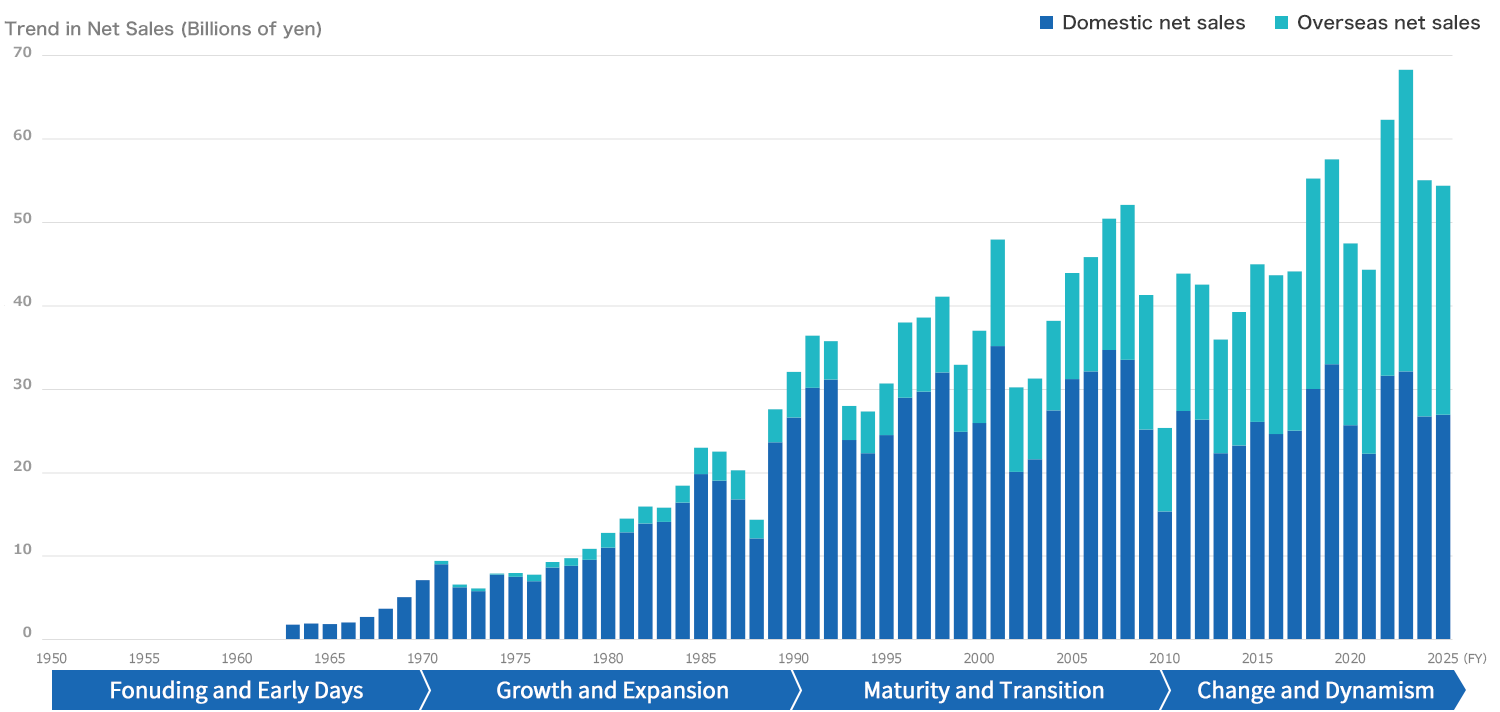

Sustainability Nippon Thompson's Value Creation: Value Creation Trajectory

Value Creation Trajectory

Daiichi-Kogyo Co., Ltd., the predecessor of Nippon Thompson Co., Ltd., is established.

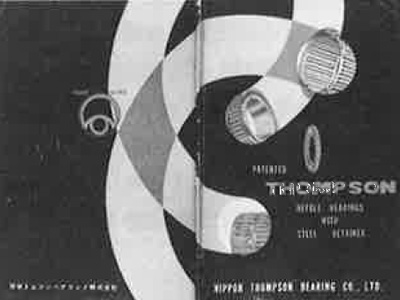

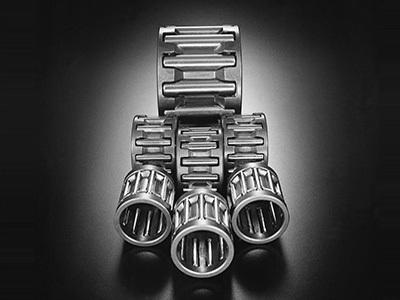

Began R&D for needle roller bearings.

Began production of needle roller bearings incorporating thin needle-shaped rollers. Catalogs at that time show items that are still being manufactured and sold today.

Established the Himeji Factory.

A motorcycle with needle cages for engine connecting rods won first place in the Isle of Man Tourist Trophy (TT) motorcycle race in Great Britain, attracting much attention.

Changed the company name to Nippon Thompson Co., Ltd. Registered and trademarked  as the corporate brand.

as the corporate brand.

Developed crossed roller bearings that can simultaneously support loads in all directions with a single bearing.

Established the Kamakura Factory.

Stock listed on the First Section of the Tokyo Stock Exchange and the Osaka Securities Exchange.

Established the Gifu factory complex.

Established IKO International, Inc. in Illinois, USA.

Established Technological Laboratory.

Established Nippon Thompson Europe B.V. in Rotterdam, the Netherlands.

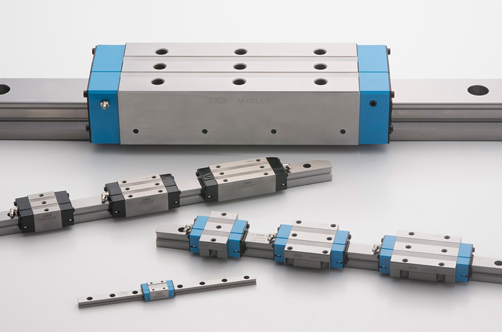

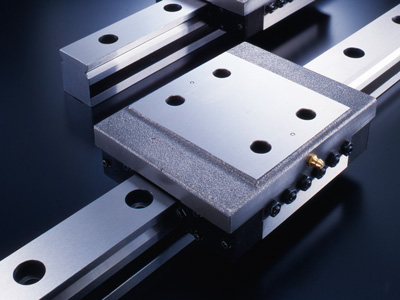

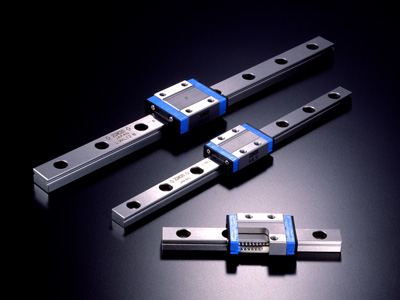

Introduced linear motion rolling guides, an evolution of rotary bearings to linear motion.

Entered into a capital alliance with Daruma- Sangyo Co., Ltd. in Gifu (currently a consolidated subsidiary: Nippon DIC Co., Ltd. in Nagoya).

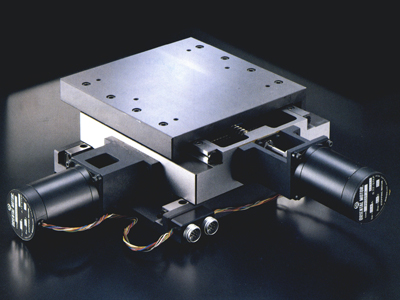

Introduced a modular product incorporating the Linear series, ball screws, and motors.

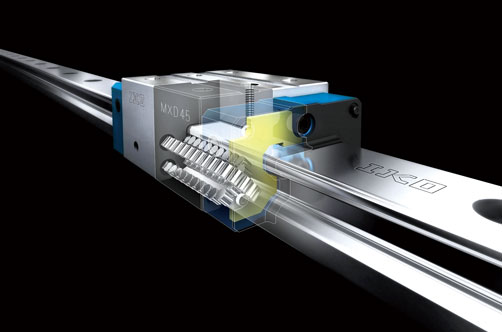

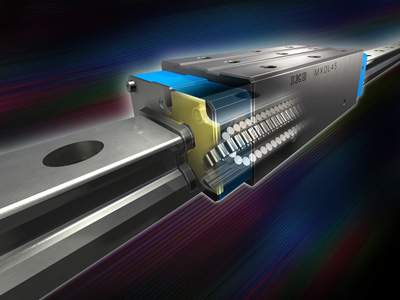

Introduced the world's first roller recirculating type linear motion rolling guide.

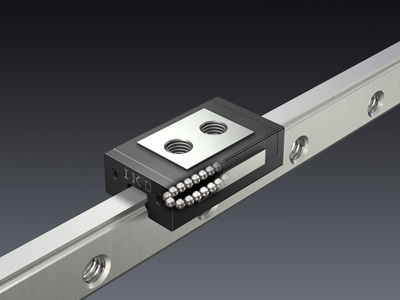

Launched a high-precision linear motor-driven stage in a rigorous pursuit of compactness.

Acquired the ISO 9002 quality management system certification (later shifted to ISO 9001) for the Gifu factory complex sequentially.

Acquired the ISO 14001 environmental management system certification for the Gifu District (also certified in the Kamakura District in 2003).

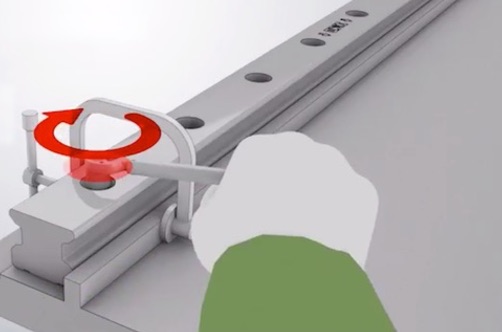

Launched a maintenance-free series of linear motion rolling guide.

* IKO's proprietary lubrication component, C-Lube, is used in many of our products. C-Lube minimizes the use of lubrication oil and supplies the optimal amount of lubrication oil for long period, so it is maintenance free over the long term and contributes to preserving the global environment.

Established IKO-Thompson (Shanghai) Ltd. (China).

Established IKO Thompson Vietnam Co., Ltd. in Vietnam.

Launched ultra-compact ball screw drive stages.

Established IKO Thompson Asia Co., Ltd. in Thailand.

Launched the linear roller way, which achieves the ultimate in high precision (low fluctuation specification).

Acquired two companies engaged in the manufacturing and sales of bearings in China; UBC (Shanghai) Precision Bearing Mfg. Co., Ltd. and UBC (Suzhou) Bearing Co., Ltd.

Launched the world's first liquid crystal lubrication linear way.

Linear Way L is used for NASA Mars rover.

Transferred shares to the Tokyo Stock Exchange Prime Market.

Transitioned to a company with an Audit and Supervisory Committee.