Linear Motion Rolling Guides Linear Way U Series

Linear Motion Rolling Guides Linear Way U Series

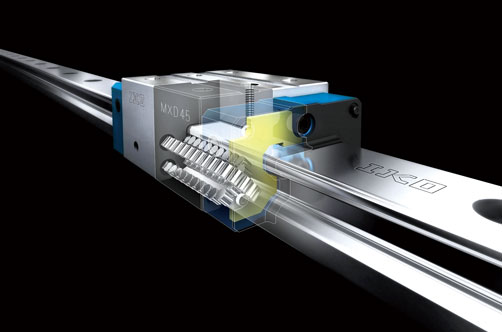

The IKO Linear Way U is a linear motion rolling guide with a structure containing a raceway inside the U-section track rail and a slide unit in its interior. With the U-shaped track rail, rigidity against the track rail moment load and torsion is significantly improved. Therefore, it is possible to not only fix the track rail to the mounting base as conventionally done, but to use the track rail as a structure beam, such as a cantilever or double-ended support in machines and equipment.

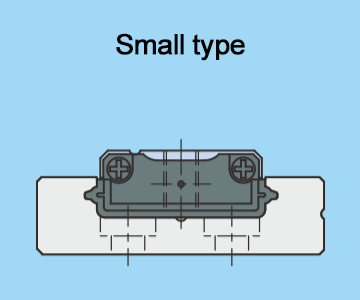

C-Lube Linear Way MUL

C-Lube Linear Way MUL is a U-Series linear motion rolling guide with a U-shaped track rail cross-section and built-in C-Lube lubrication that provides long-term, maintenance-free operation.

Maintenance-Free

Our C-Lube technology maintains the lubrication performance for an extended period of time, reducing lubrication schedules and the time it takes to manage them.

Lightweight and Compact

Since C-Lube is built into the small Linear Way U, it is lightweight and compact with the same outside dimensions.

Stainless Steel

Stainless steel types, with excellent corrosion resistance, are also available. They are ideal for use in clean rooms for medical equipment, various disc readers and semiconductor manufacturing devices.

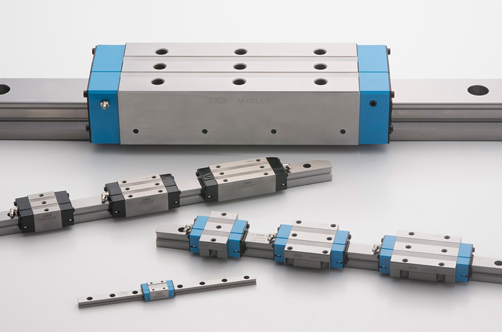

Linear Way U

U-Shaped Track Rail

By adopting a revolutionary U-shaped track rail, the rigidity of the track rail under moment load and torsion is greatly increased. The track rail can be used as a structure beam, such as a cantilever or double-ended support, in machines and equipment providing greater freedom with assembly.

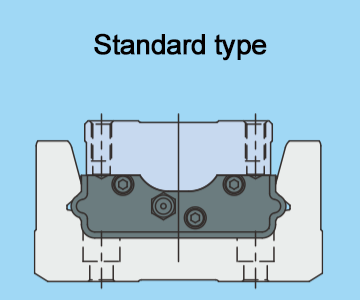

High Accuracy and High Rigidity

Since the slide unit has a structure where two rows of large-diameter steel balls come in contact with the raceway at four points, stable accuracy and rigidity can be achieved even in applications where applied load that fluctuates in direction or size and complex load are applied.

Compact Shape and Low Cross Sectional Height

Since the slide unit and track rail are compact with their sectional height as low as possible, there is more flexibility in designing peripheral devices, such as drive mechanisms. This contributes to reducing the size and weight of the machinery or equipment.

Ball Retention

The slide unit incorporates a ball retaining band which prevents the ball from dropping down when the slide unit is removed from the track rail, making it easy to handle.

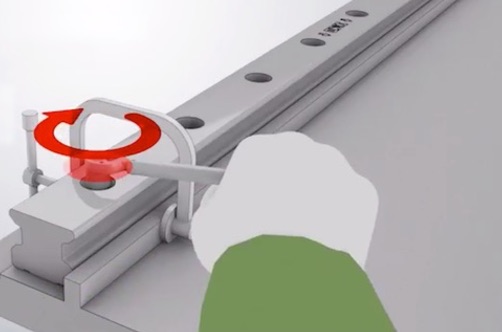

Additional Machining Options for Various Needs

Additional modifications are possible and mechanical components, such as a drive mechanism, can be fixed directly onto the track rail. However, additional modifications are not possible around the track rail raceway. For detailed information on the scope of additional modifications, please contact IKO.

Line-Up

| Product | Material | Shape | Model | Size | |||||

|---|---|---|---|---|---|---|---|---|---|

| 25 | 30 | 40 | 50 | 60 | 86 | ||||

| Linear Way U | High carbon steel made |

|

LWU…B | - | - | ○ | ○ | ○ | ○ |

| C-Lube Linear Way MUL | Stainless steel made |

|

MUL | ○ | ○ | - | - | - | - |

Special Specifications

Caps for rail mounting holes

Dedicated caps for rail mounting holes are included. They close track rail mounting holes to improve sealing property in a motion direction. Contact IKO for aluminum alloy caps for rail mounting holes.

Black chrome surface treatment

Acrylate resin coating is applied to improve the rust prevention property after black impregnated chrome surface treatment.

Upper seal

The seal is attached to the upper end of the slide unit to prevent foreign substances from entering from above.

With C-Lube plate

The C-Lube impregnated with lubricant is attached inside the end seal of the slide unit, so that the interval for reapplicating lubricant can be extended.