Sustainability ESG Management: The Environment / Environmental Considerations during Business Operations

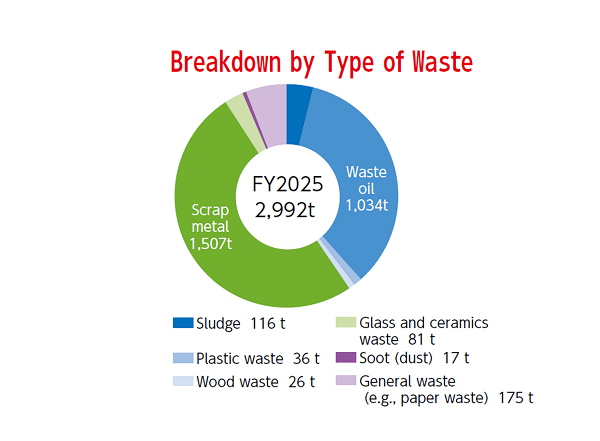

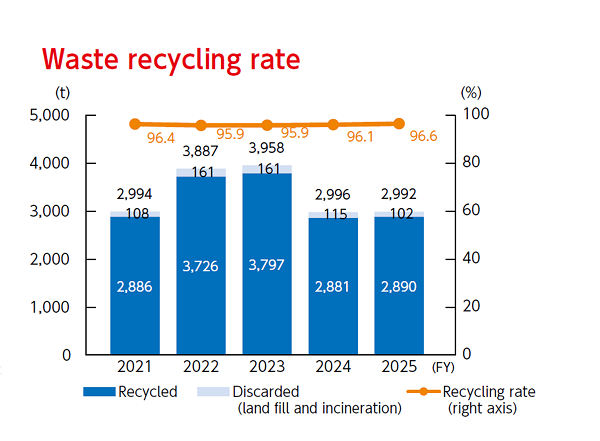

Resource Recycling (Waste)

Efforts toward the Creation of a Recycling-Oriented Society

In order to create a recycling-oriented society, the Group works to reduce waste and improve recycling rates. Our medium- to long-term goals to reduce waste are a “recycling rate of at least 96% in FY2031, and at least a 92% reduction in final disposal volume by FY2026 compared to FY2001.”

Our primary efforts to reach these targets include compressing scrap metal (grinding sludge), which is industrial waste, reusing packing materials by using special boxes for transportation, and cutting the use of cushioning materials by replacing packing materials. We have also cut the use of plastic containers at our factory cafeterias and advanced the conversion of documents into digital files to go paperless, among others, in order to actively pursue waste reduction.

Main Initiatives

Introduction of industrial waste recycling

Metal scrap (grinding sludge), a byproduct of the grinding process, is both highly moist and difficult to dispose of, so in the past it was sent to landfills by specialized companies. However, in light of our social role in building a recycling-oriented society, we are now compressing and reducing the volume of metal scrap (grinding sludge) in-house in order to recycle it.

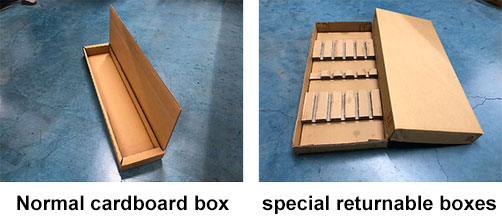

Shipping with special reusable boxes to save resources

Special, strong cardboard boxes are used for packaging our products, which are precision parts.

Generally, these cardboard boxes are recycled after delivery. However, for some of our customers, we use special returnable boxes. The returnable boxes are collected and then reused for the next shipment.

This allows us to effectively utilize limited resources.

Efforts to Ensure Proper Chemicals Management

With the reduction of environmentally hazardous substances set out in its Environmental Policy, the Group works to cut chemicals discharged from manufacturing processes and properly manage chemicals contained in its products.

We have a systematic process in place for managing chemicals contained in our products in accordance with the Guide to the Management of Chemicals Contained in Products. In 2003, we established the IKO Green Procurement Standard. Since then, we have conducted inspections of chemicals contained in products to pursue green procurement with our business partners’ understanding and help. We also continue our action to discontinue the use of designated hazardous substances specified in regulatory laws on hazardous substances around the world, including the Directive on the Restriction of Hazardous Substances in Electrical and Electronic Equipment (RoHS), the Regulation on the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), and the Toxic Substances Control Act (TSCA).

In regard to chemicals discharged from manufacturing processes in Japan, we strictly manage the quantities of the substances subject to the Law concerning Pollutant Release and Transfer Register (PRTR Law), and report how much of these substances we have handled, discharged, and transported each year to the municipalities. Methyl naphthalene, a chemical that we must include in our report, is contained in heavy oil used to fuel our air-conditioning units. To reduce the emissions and transported quantities of this chemical to zero, we plan to replace all air-conditioning units fueled by heavy oil to electric ones by FY2031. We will also advance electrification to help cut CO2 emissions.

| Substance name | Main applications | FY2021 | FY2022 | FY2023 | FY2024 | FY2025 |

|---|---|---|---|---|---|---|

| Methyl naphthalene | Fuel | 12 | 27 | 27 | 15 | 17 |

| Methylene bis (4,1-phenylene) diisocyanate |

Packing cushioning material | 0 | 5 | 6 | 6 | 0 |

| Trimethylbenzene | Fuel | 0 | 0 | 0 | 5 | 0 |

Green Procurement

The Company Group is proactively working to help preserve the global environment.

Since the 1998 fiscal year, NIPPON THOMPSON has been engaging in corporate activities in harmony with our basic philosophy, which is “to accomplish environment-friendly corporate activities as corporate social responsibility, reduce our environmental loads, and contribute to fulfillment of rich global environment.”

We believe that delivering environmentally-friendly products to our customers will help to preserve the environment. In 2003, “Green Procurement Standard” were established for promoting green procurement based on the understanding and cooperation of our business partners.

Based on this standard, we investigate and assess the load placed on the environment by our business partners and procured goods, and endeavor to promote Green Procurement together with our business partners in order to help create a rich global environment.

Compliance with the EU’s RoHS Directive

All products (standard products) are in compliance with the EU’s RoHS10 Directive in accordance with our own environmental management standards

Our products (standard products) are produced at a quality level that has received ISO-14001 and ISO-9001 certification based on our management systems that reduce load on the global environment. All of our products are also in compliance with the EU’s RoHS10 Directive.

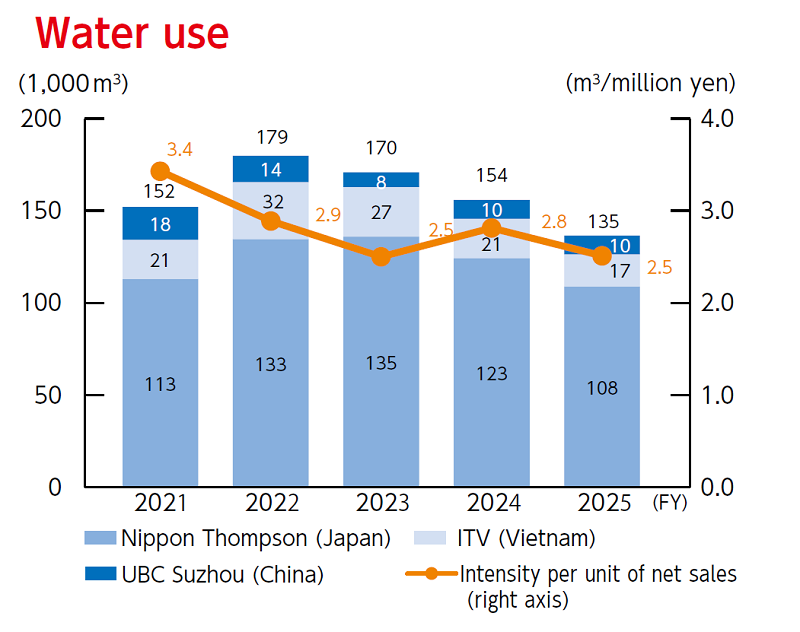

Water Resources

Initiatives for Water Resource Conservation

The Gifu area, the Group’s main domestic production base, is located by the Nagara River, one of Japan’s three cleanest rivers. As such, we believe that managing water resources is a key issue in terms of environmental conservation.

The primary sources of water supply for our business activities are tap water and well water, which are used mostly as cooling water or to make grinding fluid needed in the production process.

Yet, essentially, we use a circular system for these applications of water. That is, we use equipment designed to minimize water use by adding only the amount of water that has been naturally evaporated. We have also replaced hot-water boilers and water-cooled cooling towers with air-cooled equipment as part of the systematic course of action we take to cut water use.