Sustainability ESG Management: The Environment / Responding to Carbon Neutrality (TCFD Recommendations)

Responding to Carbon Neutrality - Endorsement of the TCFD Recommendations -

The Nippon Thompson Group (the “Group”) announced its endorsement of the “Task Force on Climate-related Financial Disclosures (TCFD)” in January of 2023 in recognition of “Climate Change” as an important business challenge.

The Group is promoting sustainable management through corporate activities in order to achieve both sustainable growth and the possibility of a sustainable society. Based on our management philosophy of being “A Company Centered on Technology Development that Contributes to Society” we have identified IKO Group Materialities (important issues) from among various social issues and have implemented various initiatives for these. As one of these Materialities, we are focusing on “implementing corporate activities to realize a prosperous global environment” in response to climate change, and are disclosing the following important information related to climate change based on the TCFD recommendations.

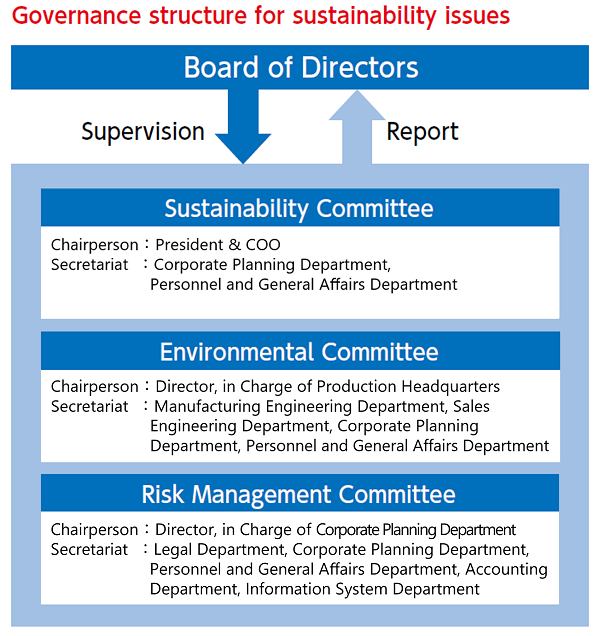

Governance

In January 2022, the Group established a “Sustainability Committee” that is comprised of Company Directors with the President and COO as the Chairperson. This committee holds meetings at least once every half period with the Corporate Planning Department and Personnel and General Affairs Department as the Secretariat Office, formulates basic policies on sustainability including climate-related and nature-related issues, establishes promotion systems, identifies medium- and long-term risks and opportunities, formulates and reviews materiality, issues and transition plan, and conducts regular reviews of implementation progress. These contents are then reported to the Board of Directors at least once every half period, and the Board of Directors oversees and gives guidance on the implementation progress of medium- and long-term targets as well as on risks and opportunities related to Sustainability issues for the whole Group. Furthermore, the Group has decided to link executive compensation to the reduction in greenhouse gas emissions and is working to strengthen the management system, which contributes to increasing corporate value from a medium- to long-term perspective by addressing sustainability issues.

Regarding the engagement with the entire supply chain, the secretariats of the Sustainability Committee and the Environmental Committee are primarily responsible for coordinating with the departments that serve as contact points with each supplier, operating as a unified team to carry out initiatives.

The Group has positioned initiatives such as measures for climate change and conserving biodiversity as important issues for sustainable management, and is working under this promotion system to strengthen initiatives by each department.

Strategy

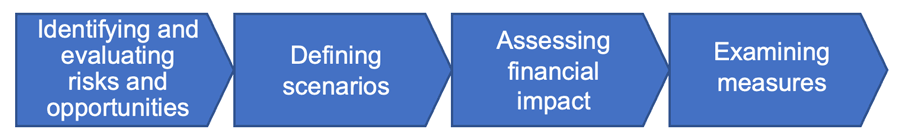

Risks and opportunities where climate change issues impact the Group business were assessed according to the following steps by referencing each risk/opportunity item indicated in the TCFD recommendations.

Analysis of policy and market trend transitions (transition risks/opportunities), and analysis of physical changes caused by disasters, etc. (physical risks/opportunities) were also conducted using the 1.5°C to 2°C scenario and 4°C scenario.

Analysis Process

Impact and Measures for Risks and Opportunities

| Risk | Factor | Impact on Business | Time Axis | Financial Impact | Measures | |

|---|---|---|---|---|---|---|

Transition Risk |

Policies and Regulations | Carbon tax implementation / Increase in carbon tax rate | - Increased burden from carbon tax | Medium to long term | Medium | - Implementing renewable energy - Implementing energy-saving equipment - Developing of low-carbon products based on carbon footprint calculation |

| - Rising costs for raw materials due to carbon tax implementation | Medium to long term | Major | - Purchasing low carbon materials and parts - Developing new low-carbon materials through collaboration with suppliers |

|||

| Technology | Implementation of low-carbon equipment | - Increased investment in latest equipment | Medium term | Medium | - Considering investment through implementing ICP (Internal Carbon Pricing) | |

| Popularization of renewable energy | - Increased costs for electricity due to rising short-term power generation costs | Short to medium term | Medium | - Construction of solar power stations at on-site/off-site, and formulating/implementing introduction plans - Realizing 100% renewable energy use at each business site through various means based on “Additionality” |

||

| Market | Changes in customer demand | - Decreased demand for carbon negative business | Medium term | Major | - Shifting to products that contribute to low carbon emissions - Working to achieve longer product life - Improving the response level to meet diversifying demands |

|

| Reputation | Slow response to climate change | - Reduced sales in the European and US markets due to insufficient climate change measures and information disclosure | Short to medium term | Major | - Implementing proper climate change measures and enhancing information disclosure | |

Physical risk |

Chronic | Average temperature rise | - Lower employee productivity due to worsening work environment | Long term | Major | - Adding break rooms and installing spot air conditioners |

| - Higher electricity costs due to increased use of air conditioning in heat treatment / surface treatment processes | Medium to long term | Medium | - Implementing energy-saving air conditioners - Improving overall equipment effectiveness |

|||

| Rising sea levels | - Lower production capacity resulting from disaster impact at company manufacturing bases (Production bases in Vietnam and China) | Medium to long term | Major | - Formulating and continuous review of BCP at factories | ||

| - Lower capacity utilization resulting from disaster impact to major suppliers | Medium to long term | Major | - Expanding suppliers - Formulating and continuous review of BCP at each supplier |

|||

| - Increased costs for factory transfer (Production bases in Vietnam and China) | Medium to long term | Major | - Promoting investment in disaster mitigation | |||

| Acute | Intensification of extreme weather | - Lowered production capacity caused by damage to company production bases due to flooding, and higher costs for handling damaged equipment (Production bases in Japan) | Medium to long term | Major | - Regularly confirming hazard maps and reviewing the BCP - Promoting investment in disaster mitigation |

|

Opportunities |

Resource efficiency | Valuation of unused resources | - Reduction of slow moving inventory and costs for handling waste by reuse of rail mill ends | Short to medium term | Medium | - Improving the accuracy of demand forecasting - Reviewing operations for improving reuse rate |

| Reduced CO2 emissions | - Reduced burden from carbon tax | Medium to long term | Medium | - Implementing renewable energy - Implementing energy-saving equipment |

||

| Energy source | Popularization of renewable energy | - Reduced costs for purchasing electricity by reducing power generation costs from a long-term perspective | Long term | Medium | - Procuring renewable energy through various means | |

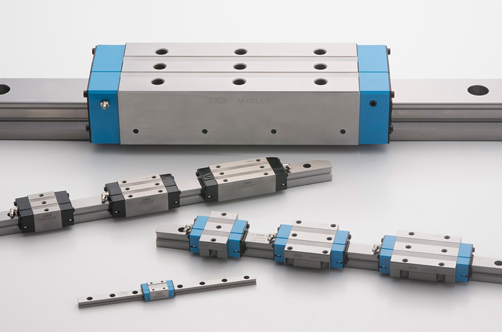

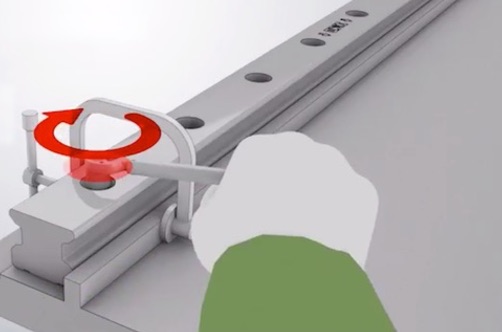

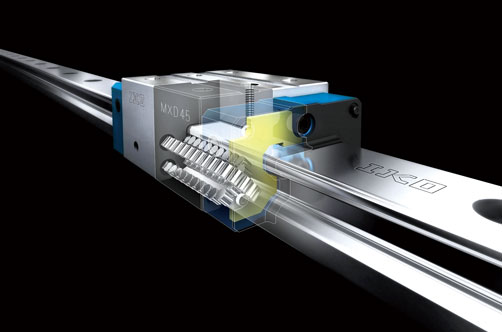

| Products and services | Contribution toward transitioning to a decarbonized society | - Increasing demand for low-friction, durable bearings - Increasing demand for “the oil-minimum” products - Increasing customization demand according to customers |

Medium term | Major | - Improving accuracy of demand predictions for efficient production, and shortening delivery dates by improving production lead time - Developing “the oil-minimum” products |

|

| Market | Promotion of electrification | - Increasing demand for the mechatronics series and Mech-unit products - Increasing demand for bearings due to increased drive components |

Short to medium term | Major | - Strengthening production capabilities by collaborating with partner companies - Strengthening global production system including construction of new factories |

|

| Expansion of the EV and storage battery markets | - Increased demand for linear motion rolling guides and liquid crystal lubricants | Short to medium term | Major | - Enhancing production capacity to meet future demand growth - Strengthening global production system including construction of new factories |

||

| Resilience | Expansion of products compatible with the BCP | - Increase in demand for company products as disaster mitigation devices | Medium to long term | Major | - Pursuing high-rigidity and quality | |

* Assumed period Short term: Up to FY2027 / Medium term: FY2028 to FY2031 / Long term: FY2032 to FY2051

* Financial impact assessments of risks and opportunities were conducted according to qualitative and quantitative impact on sales or profit based on published reports and advice from experts etc., and then categorized as either Major, Medium, or Minor.

Risk Management

Process for identifying and assessing climate-related risks

The Sustainability Committee holds discussions to identify risks and their impact on sustainable corporate activities for the Group in regards to climate change, which are included in the specified “IKO Group Materiality,” and gives a report on this to the Board of Directors twice per fiscal year. Also, in order to establish a management system for prevention, discovery, correction, and recurrence prevention for any risks that can occur related to business management including climate change risks, and to determine policies for responding to risks that occur, we established a “Risk Management Committee” comprised of Inside Directors including the President and COO and full-time Audit & Supervisory Committee member, and built a risk management system.

Process for managing climate-related risks

The “Risk Management Committee” clarifies the orientation for controlling risks based on the risk assessment results conducted every year according to the “Risk Management Regulations,” and determines which departments or organization (committee, meeting body, etc.) need to respond for each identified risk item including climate change risks for implementing risk responses.

We have been conducting large-scale risk assessments every three years to prioritize response to risks and identify risks that require the implementation of measures. Specifically, risks that need to be monitored and newly recognized risks are clarified based on the current status of risk measures. The probability of risk occurrence, impact of the risk on corporate value, and the response status to the risks are assessed, and we then identify the priority risks that need to be addressed.

Moreover, after items extracted as transition/physical risks related to climate change using “Urgency” and “Financial Impact” related to the Group are assessed according to three levels, mapping is performed using two axes, and we then evaluate the “Importance Level,” which is a total of the “Urgency” and “Financial Impact.” The “Difficulty Level” of measures for each item is being evaluated using “High (1.0), Medium (2.0), and Low (3.0),” and the priority of measures is evaluated according to the “Priority Level,” which is calculated by multiplying the “Importance Level” and “Difficulty Level.”

Process for integrating climate-related risks into corporate risk management

Principally, the “Risk Management Committee” holds meetings every half period, report contents on the response status for each risk item are assessed, important decisions are made on organization-wide risk management including climate change risks, and discussion contents are reported to the Board of Directors.

For more information on the whole Group’s comprehensive risk management, see here.

Metrics and Targets

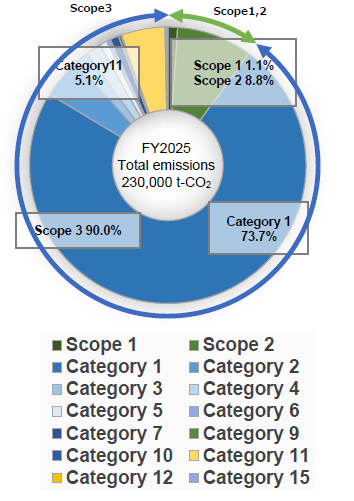

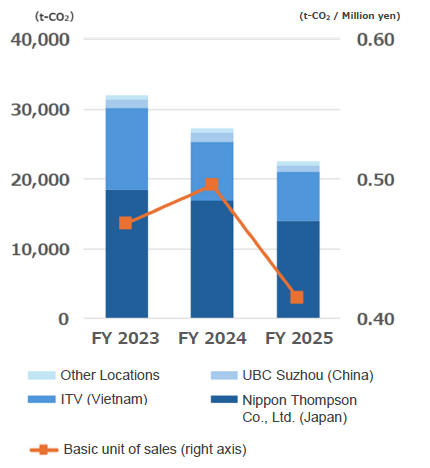

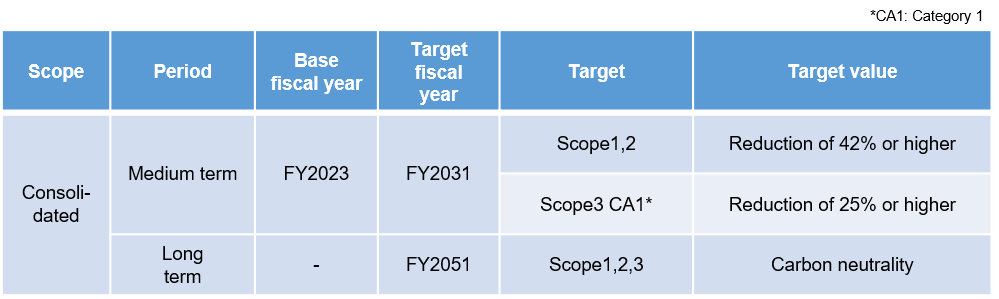

The Group calculates greenhouse gas emissions based on GHG Protocol standards for assessing and controlling the impact of climate-related issues on management. Our Group‘s emission reduction targets were set as ambitious goals in line with the level required under the Paris Agreement, and obtained SBTi* certification in October 2024. For Scope 1 and Scope 2 emissions, our goal is to achieve a reduction of 42% or more by FY2031 compared with FY2023, and to realize carbon neutrality by FY2051. For Scope 3 (Category 1), we aim to reduce emissions by 25% or more by FY2031 compared with FY2023, and to achieve carbon neutrality across all categories by FY2051. Going forward, in order to achieve our emissions reduction targets, we aim to make approximately 50% of the electricity used at our sites renewable by FY2031.

Greenhouse gas emissions are calculated using the “Asuene” CO2 emissions visualization cloud by Asuene Inc. Regarding Scope 3 emissions, following the acquisition of SBTi certification, we have recalculated the amounts for previous years as well, using a calculation method that complies with GHG Protocol standards. Specifically, this includes the addition of a calculation target category, a change to the calculation using Well to Wheel, and the addition of Category 15 for non-consolidated subsidiaries.

Greenhouse gas emissions (Scope 1, 2, and 3)

Scope 1 and 2 emission trends (Individual, production departments outside Japan)

IKO Group Greenhouse Gas Emission Reduction Targets

Initiatives to Reduce Greenhouse Gas Emissions

The Group believes that reducing greenhouse gas emissions is an important issue for realizing a rich global environment. At our domestic production centers, we have been installing solar panels since August 2013. In addition to promoting employee awareness of energy conservation by visual representations of power generation, the solar panels have also contributed to reducing CO2 emissions at power companies. In November 2021, we began to promote the use of renewable energy for inhouse consumption, for example, by using solar panels to supply electricity used for production at some of our factories. Currently, we are considering installing solar panels at other domestic and overseas production centers to further increase the ratio of electricity from renewable energy sources. We are also promoting energy-saving initiatives, such as replacing air-conditioning equipment that previously used heavy oil as a heat source with electric air conditioning and replaced fluorescent and mercury lamps with LED lighting. To achieve carbon neutrality by 2050, we will further strengthen our initiatives to reduce CO2 emissions.

Implementation of solar power generation

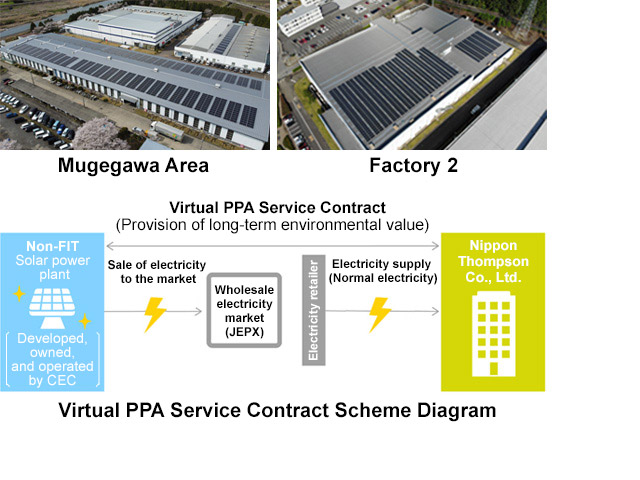

We have gradually been implementing solar power generation systems so that the electricity used at our offices is from renewable energy. In addition to onsite PPA (2 locations), we have also concluded a virtual PPA, a first in the bearing industry, and have procured about 1.81 million kWh of power. Therefore, we expect to achieve a reduction in CO2 emission of about 720 t-CO2.

When it comes to procuring renewable energy, we believe that the perspective of “Additionality” is important for creating new renewable energy in the world, and will promote procurement of renewable energy from this perspective.

Implementing Energy Reduction Patrols at factories

As part of our measures to prevent global warming, we conduct Energy Reduction Patrols every one to three months at our factory departments where energy-saving activities are being promoted. As part of these patrols, appointed members thoroughly inspect manufacturing sites. They search everywhere for hidden energy loss.

As a result of such activities, items such as air leaks at piping connection points and power supply to unused lighting and equipment were found, helping to save energy.

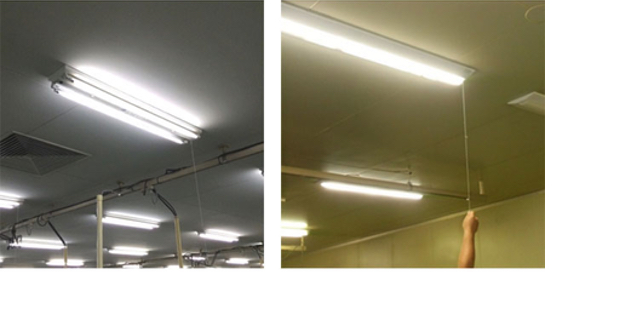

Implementation of LED lighting

In the past, our factories used fluorescent lights and mercury lamps. However, not only do these have issues that occur over time such as power consumption and deterioration of the lighting fixtures, laws and regulations are gradually becoming more and more strict (industrial waste from products containing mercury).

When updating the lighting fixtures, we first considered whether lights were really needed at that location. If lighting was actually needed, LED lights where installed, which are long-lasting, help reduce cost and save energy. Also, when changing the lighting in offices, remote switches are installed so that each employee has an awareness of saving energy.

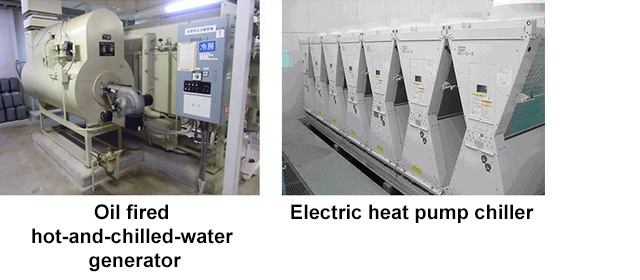

Changing the air conditioning equipment heat source from heavy oil to electricity

In the past, heavy oil was used as the heat source for our air conditioning equipment, which had various issues including use of limited resources and air pollution as well as the risk of leakage with the heavy oil tank.

When air conditioning equipment is updated, it is changed to equipment with an electric heat source. Such electric air conditioning equipment is very energy efficient, and the number of operating units can be controlled automatically according to the situation.

Since it can respond quickly to changes in load, the energy-saving rate has improved, which greatly contributes to CO2 reduction.