Linear Motion Rolling Guides Linear Ball Spline G Series

Linear Motion Rolling Guides Linear Ball Spline G Series

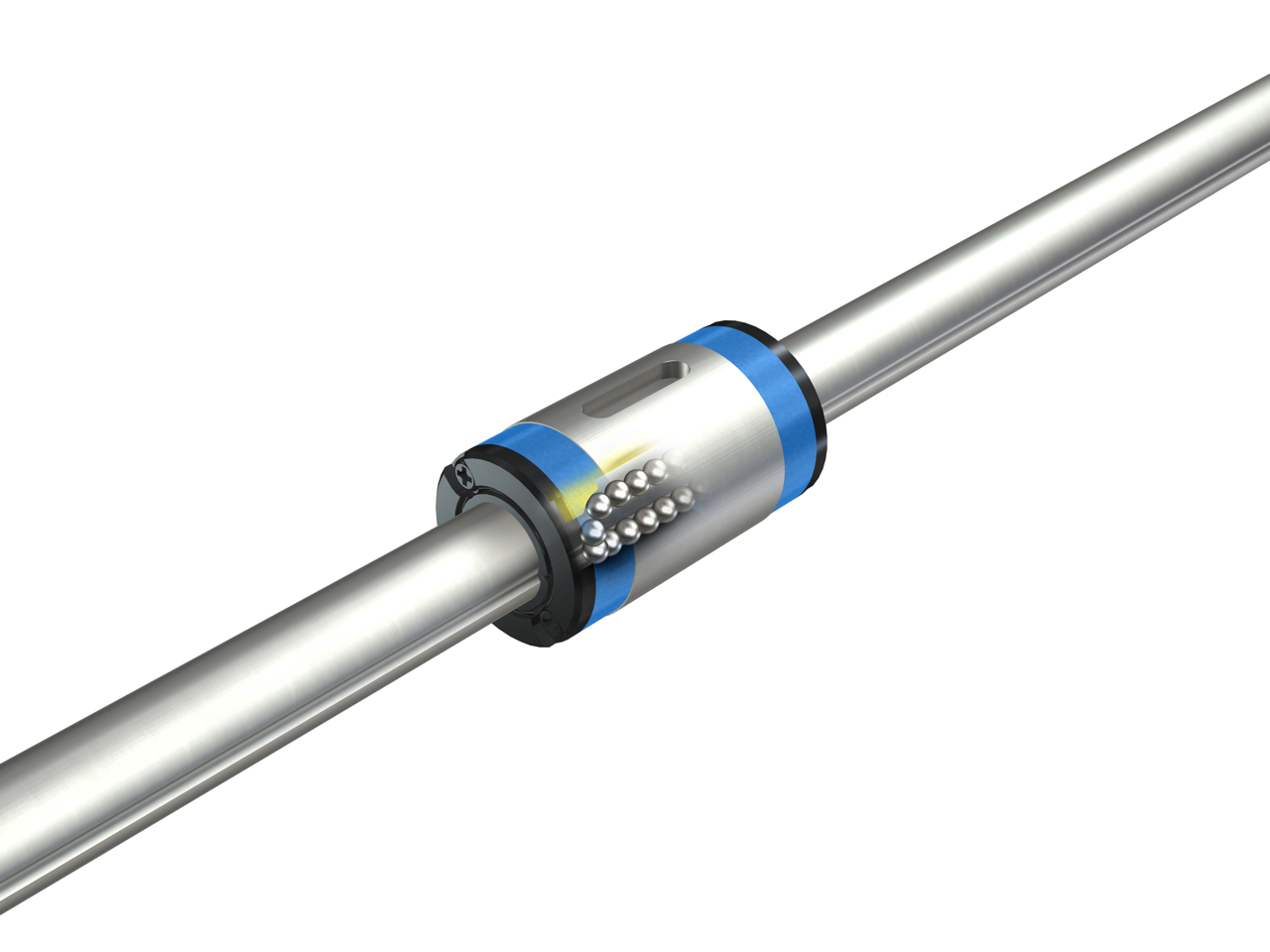

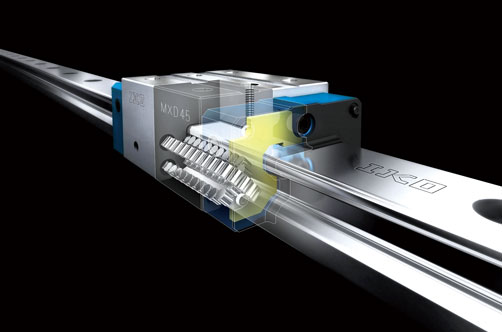

The IKO Linear Ball Spline G is a linear motion rolling guide in which an external cylinder performs endless linear motion along a spline shaft. Since two rows of steel balls come in contact with the raceway surface at four points, stable accuracy and rigidity can be achieved, even in applications where load with variable direction and size, or complex load is applied. The linear ball spline is extremely compact, thanks to its simple structure.

C-Lube Linear Ball Spline MAG

C-Lube Linear Ball Spline MAG incorporates C-Lube in the IKO Ball Spline G. MAG is used primarily in semiconductor/liquid crystal related manufacturing equipment where harsh operating conditions and high acceleration/deceleration are common. C-Lube provides long-term, maintenance free operation, and reduces the cost of the whole system by eliminating the oil supply mechanism and reducing the running cost and hours required for lubrication.

Maintenance-Free

Our C-Lube technology maintains the lubrication performance for an extended period of time, reducing lubrication schedules and the time it takes to manage them.

Linear Ball Spline G

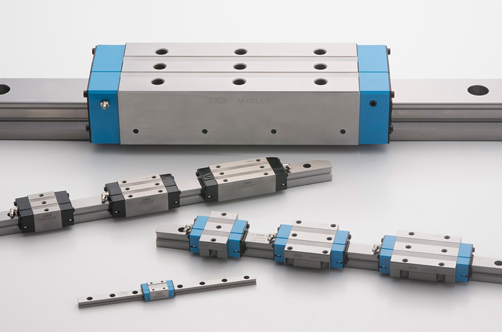

Interchangeable

Interchange specifications are available. Since the external cylinder and spline shaft dimensions are separate, each can be individually added or exchanged.

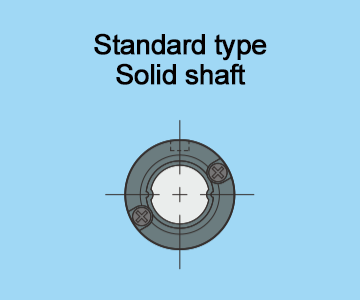

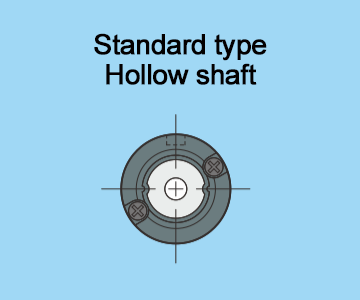

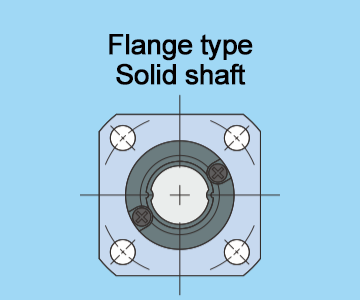

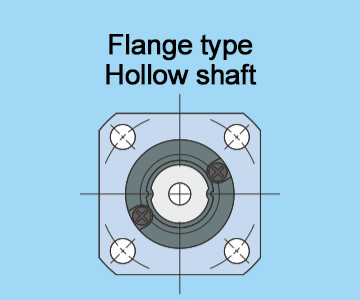

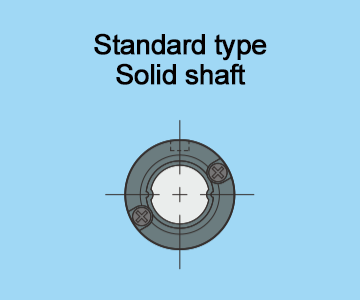

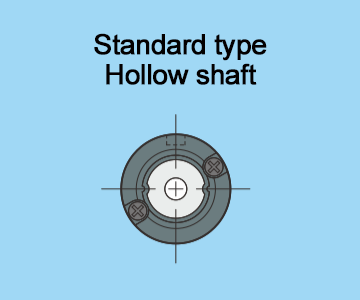

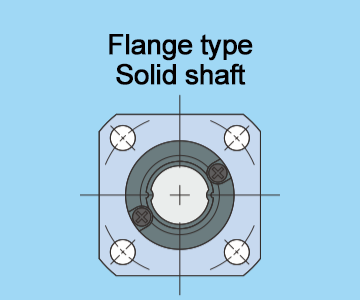

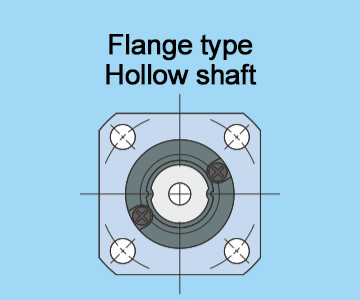

Standard Type and Flange Type

Two external cylinder shapes are available: standard (cylindrical) and flange.

External Cylinder Length

Both the standard type and flange type offer two external cylinder length options, standard and high-rigidity long. They can be used for a wide range of applications offering greater design flexibility.

Solid Shaft and Hollow Shaft

The spline shaft is available in either a solid shaft or hollow shaft, which can be selected according to the application.

Stainless Steel

A stainless steel spline shaft can be selected as an option. They are best suited for applications where rust prevention oil cannot be used, such as in a cleanroom environment.

Line-Up

C-Lube Linear Ball Spline MAG・Linear Ball Spline G

| Product | Shape | External cylinder length | Model | Size | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 | 25 | 30 | ||||

| C-Lube Linear Ball Spline MAG |

|

Standard | MAG | - | - | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - |

| Long | MAGL | - | - | ○ | ○ | ○ | ○ | - | - | - | - | - | - | ||

| C-Lube Linear Ball Spline MAG |

|

Standard | MAGT | - | - | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - |

| Long | MAGLT | - | - | ○ | ○ | ○ | ○ | - | - | - | - | - | - | ||

| C-Lube Linear Ball Spline MAG |

|

Standard | MAGF | - | - | - | ○ | ○ | ○ | ○ | ○ | - | - | - | - |

| C-Lube Linear Ball Spline MAG |

|

Standard | MAGFT | - | - | - | ○ | ○ | ○ | ○ | ○ | - | - | - | - |

| Linear Ball Spline G |

|

Standard | LSAG | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Long | LSAGL | - | - | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||

| Linear Ball Spline G |

|

Standard | LSAGT | - | - | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - |

| Long | LSAGLT | - | - | - | ○ | ○ | ○ | ○ | ○ | - | - | - | - | ||

| Linear Ball Spline G |

|

Standard | LSAGF | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Long | LSAGFL | - | - | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||

| Linear Ball Spline G |

|

Standard | LSAGFT | - | - | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - |

| Long | LSAGFTL | - | - | - | ○ | ○ | ○ | ○ | ○ | - | - | - | - | ||

*For the models indicated in , the interchangeable specification is available.

Special Specifications

Stainless steel end plate

The standard synthetic resin end plates are replaced with stainless steel end plates. The total length of the external cylinder remains unchanged.

No seal

Seals at both ends of the external cylinder can be replaced with end pressure plates, which do not come in contact with the spline shaft, to reduce frictional resistance.This specification is not effective for dust protection.

Oil hole

An oil hole is created on the external cylinder.

With C-Lube plate

The C-Lube impregnated with lubricant is attached inside the end seal of the slide unit, so that the interval for reapplicating lubricant can be extended.

Special environment seal

The standard end seal and under seal are replaced with seals for special environment that can be used at high temperatures.

Specified grease

The type of pre-packed grease can be changed by the supplemental code.

Stainless steel spline shaft

The material of the solid spline shaft is changed to stainless steel.