Sustainability Nippon Thompson's Value Creation: Business Strategy

Our Group's business is growing worldwide through the supply of machine components that are indispensable to all industries, from electronics-related industries to machine tools and transportation equipment. The core of our value creation is that we provide high-quality products that quickly meet the challenges and demands of our customers.

The IKO brand is highly credible and trusted due to the accumulation of value creation through our sincere activity to solve customers' problems in collaboration with external partners, as well as the business units responsible for the value chain.

At the same time, global society is undergoing a period of historic change, including a digital shift, the evolution of AI and IoT, and social demand for sustainability, including the SDGs. We will address issues that could be potential risks, while continuing to take on the challenge of new growth opportunities where we could leverage the Group's strengths to achieve sustainable value creation.

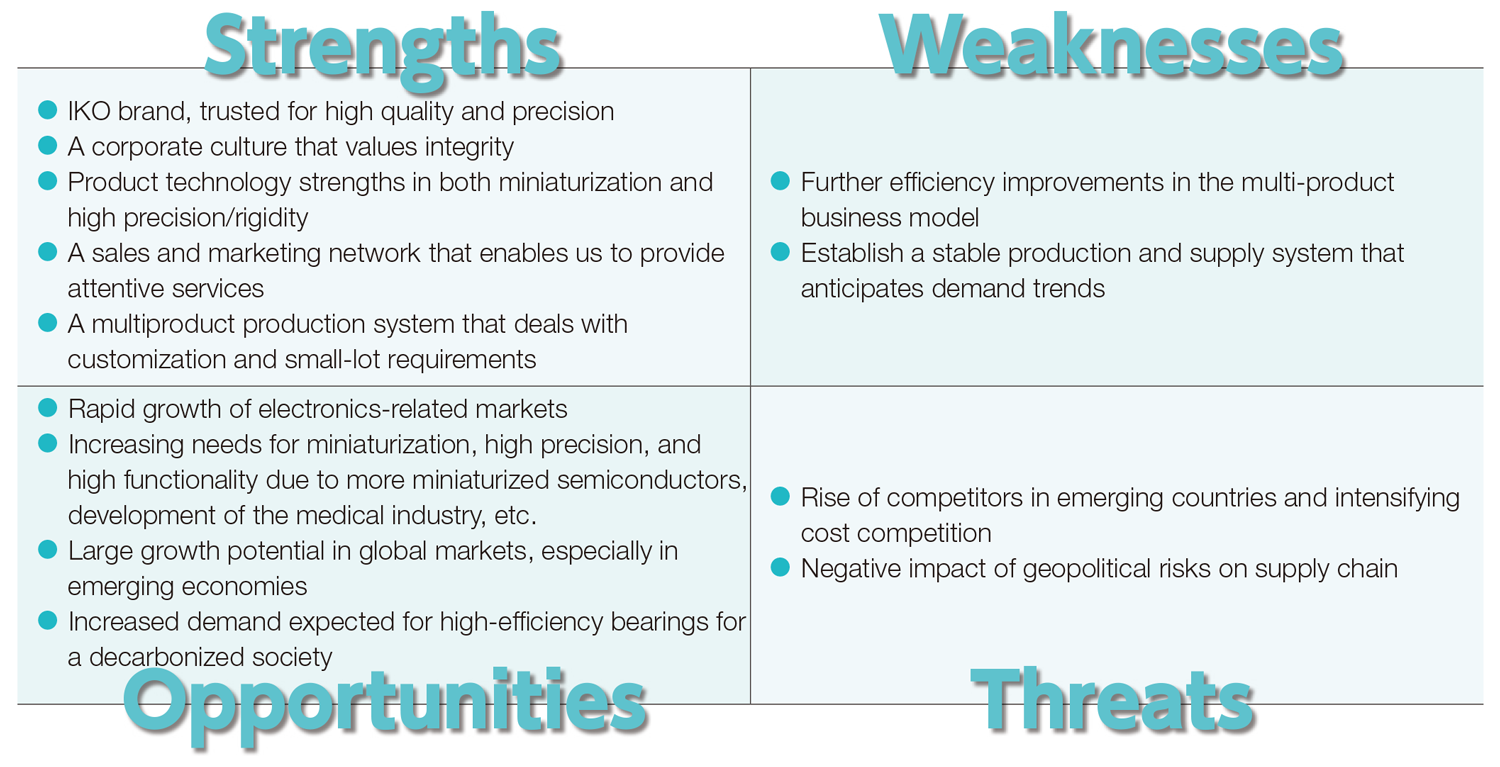

SWOT Analysis

Technology Development Headquarters

Environmental Awareness and Issues

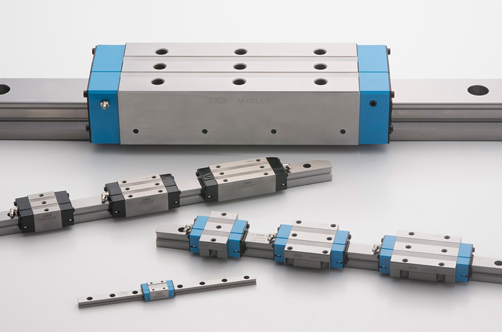

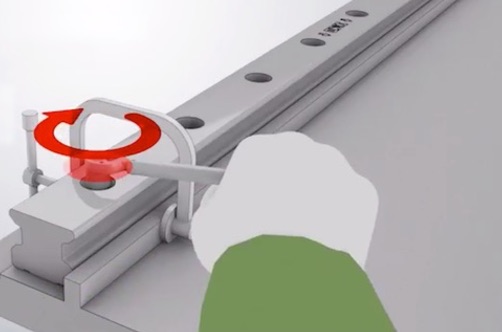

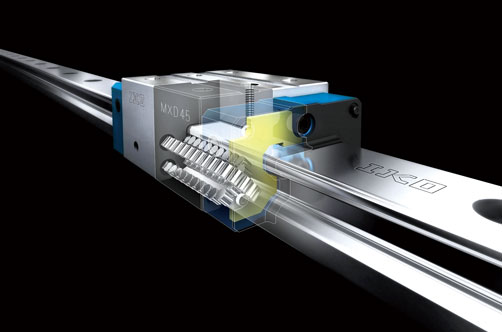

Linear motion rolling guides and bearings are mechanical components for enabling precise and smooth movement. By reducing heat generation and energy loss caused by friction, they help improve the performance of all types of machinery and equipment.

As the digital shift accelerates throughout the world, next-generation technologies such as IoT, AI, and smart factories are developing significantly, so demand for our products is expected to grow continuously. In particular, the sophistication of semiconductors and advancements in medical equipment have increased the need for bearings and components with superior specifications, such as small size, high functionality, and high accuracy, and the needs for each application are becoming far more segmented, making the technical issues more diverse and complex.

We aim to meet a wide range of requirements such as high load capacity, high rigidity, long life, low friction, low vibration, low dust generation, environmental temperature resistance, and vacuum resistance. Drawing from our expertise in roller guidance and small sizing technology, we will continue and deepen our R&D to achieve these goals.

Features and Strengths

In the Technology Development Headquarters, we prioritize our customers' requests and strive to maintain the upmost integrity capabilities in resolving any issues.

Our strong technological capabilities that support the development of the IKO brand for top-quality and highly precise products are the result of the many years of experience and knowhow that we have accumulated by working closely with the Production Headquarters to fulfill our customers’ requirements and overcome obstacles one by one.

Micro Linear Way LWL1 is the world's smallest linear motion rolling guide created based on such experience and knowhow. This product realizes high precision and stable running despite its extremely small track rail width of 1 mm, and our technological capabilities demonstrated by this product has earned the trust of NASA. The Micro Linear Way series was used on the Mars rover and realized stable running for over one year under the harsh environment on Mars, which proved that this is a highly reliable and durable product.

In order to continuously create products trusted by customers, the Technology Development Headquarters continues to work on thoroughly examining customers' issues and proposing solutions.

Policy and Future Initiatives for Achieving the Long-Term Vision IKO VISION 2030

Strengthening Technical Services to Establish the Global Business Structure

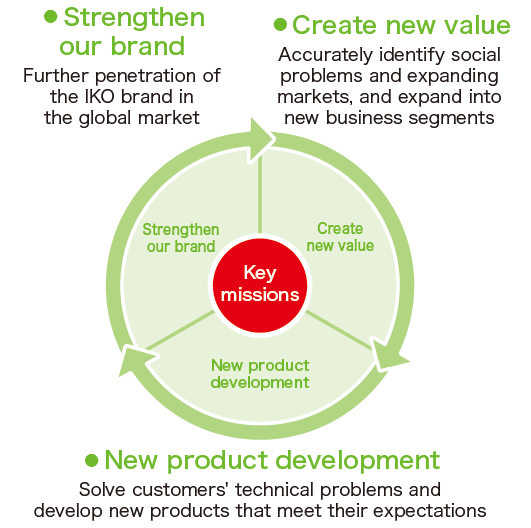

In the Technology Development Headquarters, our initiatives are aligned with key missions for new product development that more thoroughly meet existing market needs, strengthen our brand, and create new value.

In terms of new product development, we developed and announced the LRX ZERO, which achieves ultra- high-precision guide performance. With this product, we intend to meet the demands of customers, particularly from machine tool manufacturers who have been using our roller-type linear motion rolling guides for many years. In the mechatronics series, we are developing products that combine our expertise in small linear motion rolling guides and linear motors. We are also focusing on the development of custom products for customers as well as modular unit products.

In order to realize IKO VISION 2030, it is necessary to accurately identify regions with high market growth potential for semiconductor manufacturing equipment, industrial robots and medical equipment, which we have developed as our key industries, and concentrate our resources on those regions. By adding regional characteristics around the world to our strength of identifying potential issues of customers and proposing optimal solutions, we will launch high-value-added products. We will also promote building a technical support system utilizing our global offices in order to further strengthen customer services.

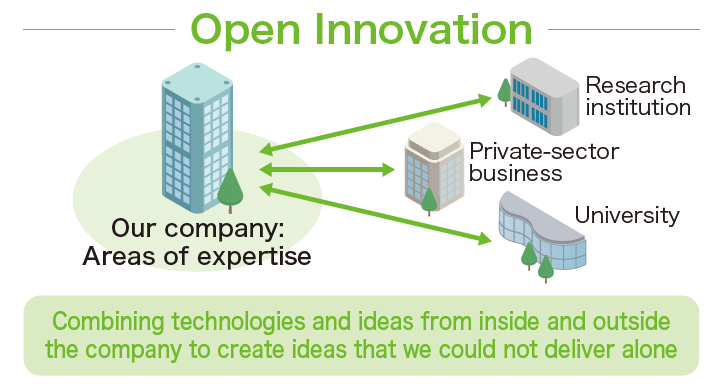

Using Open Innovation to Deepen Technology

In the Technology Development Headquarters, we continue to explore new technologies and new business segments as we work to achieve our long-term vision. In addition, we aim to develop new application products while not only relying on in-house technologies but also strengthening cooperation with universities, research institutions, and other companies. A prime example is liquid crystal lubricant, which we have jointly developed with the University of Yamanashi. This lubricant has excellent properties for special applications such as evaporation and outgas/dust generation. It is expected to expand the applicability of bearing mechanisms in electronic components, semiconductor manufacturing equipment, and more. In this way, we will embrace open innovation as a way of deepening technology and continuing to expand into new technologies and new business segments.

Production Headquarters

Environmental Awareness and Issues

Traditionally, the bearing industry was centered on mass production, mainly for the automotive industry. However, this is changing with the recent shift to EVs. With this change, we expect steady demand for needle roller bearings in areas that we have been focusing on. We are upgrading our multi-product manufacturing system to strengthen our competitiveness. In the linear motion rolling guide series, the main challenge is to boost supply in response to significant market growth, particularly in the semiconductor industry, as well as to reinforce our “swift response capability” to address the fluctuating business cycle. Furthermore, it is necessary to have production and purchasing that consider the environment and human rights. A healthy, safe, and rewarding work environment is another challenge we must address more than ever.

In order to solve these challenges, we are addressing the mission of globally implementing “local-based manufacturing,” which is a strength of IKO, and strengthening the sustainable global supply chains together with our suppliers.

Features and Strengths

Our greatest strength in manufacturing is our quality. It is our thorough commitment to high quality that has enabled us to gain the trust of our customers. In addition, our ability to supply a wide variety of products with such high quality is another source of the Group’s value. To meet customers’ diverse requirements promptly and accurately, the Production Headquarters is constantly upgrading the flexible production system.

In needle roller bearings, we have developed a wide range of products through to small-lot production and inventory optimization. We quickly provide these products to meet customer requirements. At the same time, in the linear motion rolling guide series, we accept orders for single customized products, including rail lengths in 1-mm increments, enabling a detailed response to our customers’ needs.

The strengths of IKO that support the IKO brand are our commitment to high quality and our unique manufacturing expertise, including equipment development, process design, production and inventory planning, and collaboration with suppliers, which enables us to optimally respond to requirements for a diverse range of products and customization.

Policy and Future Initiatives for Achieving the Long-Term Vision IKO VISION 2030

Strengthening the planning function for sophistication of production strategies

In the Production Headquarters, we are accelerating the creation of a robust production site system to realize IKO VISION 2030. In 2023, we reorganized the department based on the product series. In addition to making this organization more agile, we are strengthening the planning function to enhance the sophistication of our production strategies with the global production system.

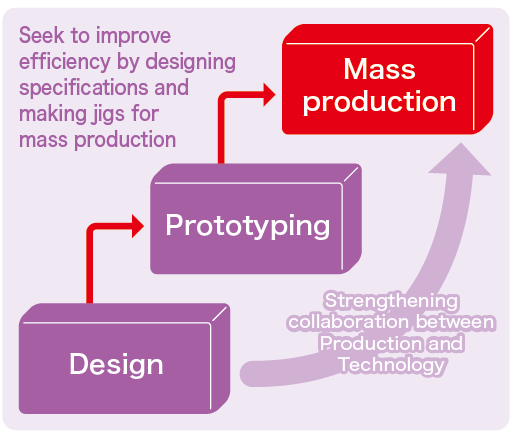

Specifically, we will enhance the planning function of the Manufacturing Innovation and Production Management, which was newly established in 2023, to build optimal production strategies utilizing our three production sites in Japan, Vietnam, and China, based on the big picture of QDC (quality, delivery, and cost) competitiveness and customer needs. From the perspective of QDC competitiveness, we will continue to promote procurement of parts and materials in the global market and strengthen strategic collaboration with our suppliers. We not only request suppliers to meet our required specifications, but also share problems with each other, and work together to find solutions to those problems in order to maximize IKO's high quality, delivery time reduction, and cost reduction. In production planning, we will work to strengthen the prototyping function, in addition to closer information exchange with the Sales & Marketing Headquarters, in order to respond to the rapid rise of the semiconductor market. In order to speed up the transfer of prototypes to factories for mass production, we will seek to improve efficiency at each of the three production sites in conjunction with the Engineering Department, such as designing specifications and making jigs with mass production in mind.

By promoting these activities, we will develop a production system with “swift response capability” to respond promptly, accurately, and flexibly to a wide variety of customers' requirements from prototyping to mass production, throughout the supply chain management including suppliers. In doing so, we will not only put the highest priority on making customers happy, but also be the first to be consulted by customers.

Development towards operation of new factory in Vietnam

As the pioneer of the next-generation IKO manufacturing, the Production Headquarters is promoting the concept of the new “IKO Production System” utilizing the new factory in Vietnam.

The new factory in Vietnam, a major pillar of our growth strategy to realize IKO VISION, will play an important role in accelerating globalization. In establishing regional sales models, the most important theme is to develop region- specific concept models and supply them at the speed demanded by customers. In order to efficiently produce concept models developed in Japan, we are addressing these issues in collaboration with various departments, including the promotion of automation and the establishment of a production system that realizes flexible production. We will also actively promote exchanges with the existing factory in Vietnam to prepare for starting maximum production with the launch of the new factory while promoting global human resource development.

Note: In our "Notice of Revision of IKO Medium-Term Business Plan 2026" dated May 12, 2025, we announced the postponement of the construction of the new plant in Vietnam, considering the delayed recovery in demand for semiconductor manufacturing equipment and related products.

By promoting growth strategies throughout the Group in this way, we will build a firmer corporate foundation and aim to realize IKO VISION through the growth of the Group's “manufacturing human resources.”

Sales & Marketing Headquarters

Environmental Awareness and Issues

Needle roller bearings are the legacy of the IKO brand, and the driving force behind the Group's growth as a profit generating source since the Company’s establishment. Linear motion rolling guides and mechatronics series are expected to grow significantly in the future as we address technological innovations, such as state-of-the-art semiconductor manufacturing equipment, robots and advanced medical equipment. Our broad, well-balanced product lineup, geared toward sustainable growth, is the result of our Sales & Marketing Headquarters’s attentive management of customer feedback, which changes over time, as well as our ability to develop products while foreseeing market trends.

To achieve carbon neutrality by 2050, there has been a rapid increase in demand for downsizing machinery and equipment to reduce greenhouse gas emissions. Therefore, we anticipate customer expectations will grow more and more in the future for Eco-Products, which are products proposed for reducing CO2 emissions. Considering these circumstances, we recognize that the mission of IKO is to align ourselves with customers’ requirements for sustainable management and expand our customer perspective solution proposals across the globe.

Features and Strengths

The IKO Group has 49 domestic and overseas sales offices (23 in Japan and 26 overseas), and we are closely attuned to our customers through product sales, accurately identifying the needs of each region, industry and customer, launching strategic products that aim to be the niche leader from a global perspective, concentrating resources in key regions and strengthening our system. We are also strengthening partnerships with highly specialized trading companies dedicated to specific customers and industries, while creating a structure that enables us to provide more extensive and attentive support.

With our legacy as a bearing trading company that was founded in 1950, the DNA of our Company has been firmly inherited by our current Sales & Marketing Headquarters. With a strong belief in proposal-based sales activities from the customer’s perspective, we have earned a high level of trust by constantly seeking to add value for our customers, not only by selling our own products, but also by providing sales and services of IKO Mech-units in collaboration with our alliance partners.

Policy and Future Initiatives for Achieving the Long-Term Vision IKO VISION 2030

Acceleration of global growth and establishment of sustainable competitive advantage

We have launched the Medium-Term Business Plan 2026, which is an important step forward to achieve the goals of IKO VISION 2030. Under the Medium-Term Business Plan 2026, we will identify important markets and regions and develop strategies in order to achieve significant growth in the global market. In particular, semiconductor manufacturing equipment, industrial robots, and medical equipment are expected to continue to grow significantly. Particularly, semiconductor manufacturing equipment is expected to continue to grow rapidly due to the sophistication of semiconductors accelerated by the expansion of generative AI. We aim for sustainable growth by quickly riding this tide and taking the initiative.

As geopolitical risks continue to rise, China is accelerating its domestic production of semiconductor manufacturing equipment. In this market environment, we will build a high-value-added business model that our competitors cannot imitate, leveraging our differentiated product lineup and excellent ability to propose solutions. Specifically, we will concentrate more on our flagship products such as linear roller way Super X, which is a roller-type linear motion rolling guide, and liquid crystal lubricant developed jointly with the University of Yamanashi. At the same time, we will also develop new markets by strengthening alliances with local partners and focusing on proposing IKO Mechunits. In order to further grow in overseas markets, we will analyze information we obtained from a global perspective and formulate appropriate strategies.

Ability to make proposals as the leading needle roller bearing manufacturer

Needle roller bearings, which have been the foundation of the IKO brand since its establishment, are our important source of profit. Unlike ordinary ball bearings, these products, which use needle-shaped rollers as rolling elements, boast a low cross-sectional height and large load capacity. They are highly regarded in a wide range of industries from transportation equipment such as automobiles and motorcycles to printing machines and construction machines, due to a wide variety of models and high quality. Our market superiority is supported by our ability to make proposals to meet diverse customer needs by utilizing a wide range of variations and sizes.

In addition, needle roller bearings for the aftermarket segment contribute to the reinforcement of the stable profit generating source that increases our corporate value. Even amid the increasing volatility of the semiconductor industry, needle roller bearings are firmly supporting our sustainable growth by their stability and high profitability. As a leading needle roller bearing manufacturer, we aim to build a firmer profit generating source by continuing to make proposals optimal to customers' challenges.