Sustainability ESG Management: Social Issues / Product Quality and Supply Chain

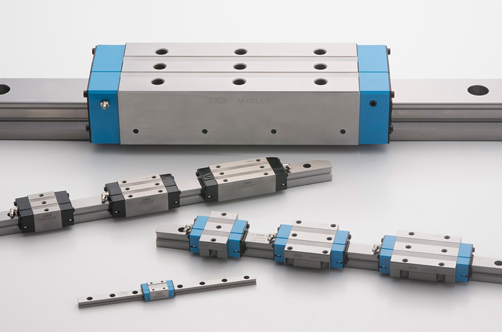

Product Quality

Basic Approach

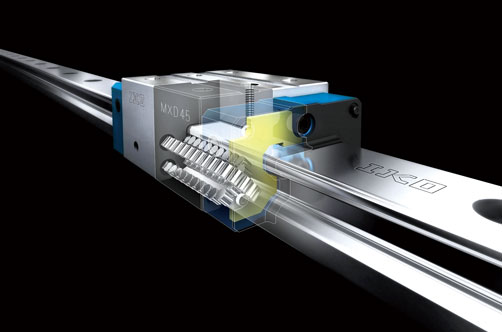

The pursuit of quality, one of the strengths of the Group, originates from our strong belief, deeply rooted in all employees throughout our long history, that we, as the whole Group, want to “continue to produce products that our customers trust and are satisfactory to them.” The Group has set the policy for quality and will maintain and improve high quality standards by repeatedly making optimal overall improvements without being content with just the status quo, and provide products that customers can use safely and comfortably.

Quality Policy

We are committed to quality first, and every one of us will

use our creativity and ingenuity to create products that

satisfy our customers. We will make improvements to

ensure that these actions remain effective.

Quality Control System and Initiatives

Global Quality Control System

The Group built its quality assurance system for its departments in Japan over the years. This system is applied to our overseas production sites in order to maintain high product quality and continue to enhance it across the Group.

To ensure efficient quality assurance activities and improve customer satisfaction, all our production sites, in Japan or overseas, have acquired the ISO 9001 certification, an international standard for quality management system (QMS). We also conduct regular and special internal quality audits to examine whether our QMS conforms to the standard and works effectively, and to make changes if necessary, thereby improving the practicality and effectiveness.

Please refer to the Company’s website (below) for the Quality Management System ISO 9001 Certificate.

https://www.ikont.co.jp/eg/company/business/bus02.html

Efforts to Improve Customer Satisfactions

Quality is the vital element of our products and at the core of the IKO brand. We make various efforts to reduce complaints received for product quality to zero.

Efforts in procurement activities: Partner company evaluation

We conduct annual partner company evaluations using criteria for quality, deliveries, and costs. We provide the evaluation results to the partner companies as our feedback so that they will work on improvements if necessary, thereby actively developing a stronger quality control system across the supply chains.

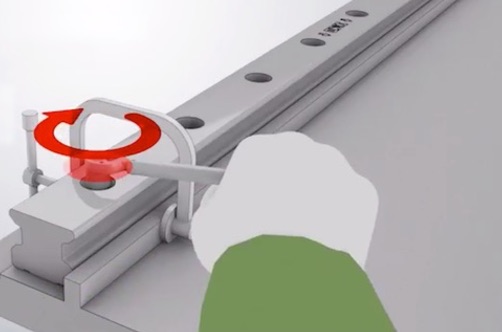

Efforts in production activities: Inspector training

As part of our quality control in production processes, we have an inspector system in place. Under this inspector system, employees in production departments who have been trained to acquire knowledge and skills related to quality inspection are certified as “Inspectors” by the Quality Control Department. The certified Inspectors are then assigned to production processes, which are subdivided, to ensure greater quality assurance.

Efforts in after-sales service

When we receive any complaint, our sales and production departments work together to take prompt action to prevent any recurrence. We also fully examine feedback received on the product while we follow up our after-sales service for the customer, and take a committed course of action to address any issues, which serves as a series of efforts to make improvements that will prevent complaints going forward.

Supply Chain Management

Basic Approach

As the Group operates globally, we believe that we should ensure responsible actions to meet public demand throughout our supply chains in order to earn the trust of the international community.

Basic Procurement Policy

- We will procure fairly and optimally from suppliers with competitive prices, focusing on quality, cost, and on-time delivery.

- We will comply with all laws and regulations and conduct fair transactions.

- We will promote green procurement as we conduct procurement that considers the global environment.

- We will build a supply chain that will develop sustainably and fulfill our social responsibilities through our corporate activities.

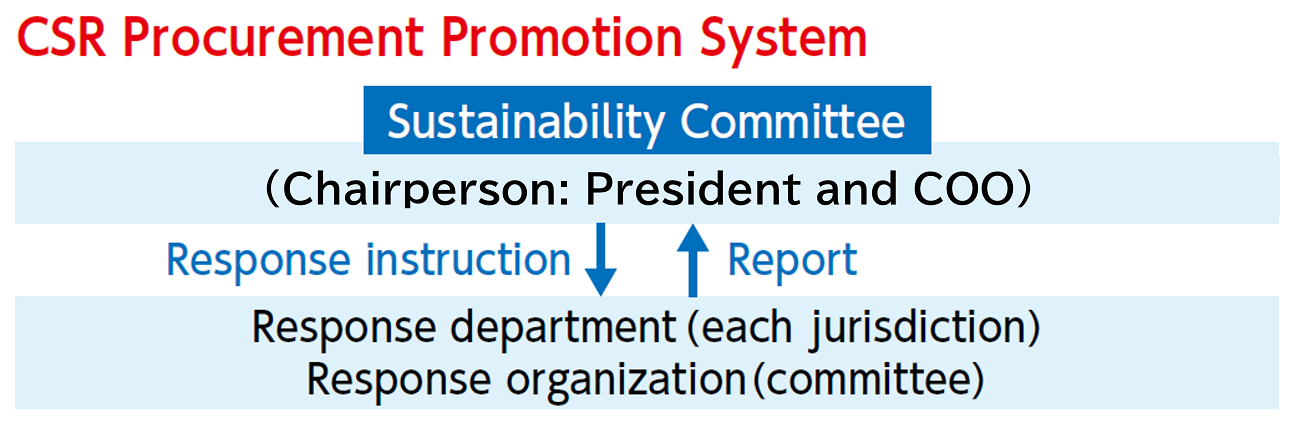

CSR Procurement Promotion System

To achieve continuous growth, it is essential for a company to responsibly comply with the law and fulfill its social responsibilities as a member of society through its corporate activities. In FY1999, we set out the guiding principles “Engage in environmentally conscious corporate activities and reduce any adverse environmental impact we may have on the environment as our corporate social responsibility, thereby helping create flourishing natural environments across the globe.” In 2003, we established the IKO Green Procurement Implementation Standards and have pursued green procurement since.

In July 2022, we formulated the IKO Group Supplier CSR Procurement Guidelines to fulfill our social responsibilities, including a consideration of human rights and labor issues as well as environmental issues. We also conducted a survey on suppliers’ intention to support and comply with these guidelines and the procurement policy, and received responses from 273 companies. We will continue to work closely with our suppliers to promote the use of the guidelines and put greater effort into ensuring CSR procurement in order to keep improving the effectiveness of the guidelines.

What We Do

The Group has been taking a variety of actions in order to create supply chains that continue to develop and fulfill social responsibilities. Specifically, to comply with regulations on conflict minerals, we conducted a survey of 220 suppliers to see if they use any conflict minerals, applying the industry’s common format. With the results, we have confirmed that our procured products are safe.

We also worked to partner with other businesses from a completely new point of view and submitted our Declaration of Partnership Building with the aim of creating high added-value and enhancing resilience across our supply chains. Moreover, we hold a workshop on subcontract-related laws led by a guest instructor as part of our efforts to observe the promotion standards.

We endorse the aim of the White Logistics Movement promoted by the Ministry of Land, Infrastructure, Transport and Tourism; the Ministry of Economy, Trade and Industry; and the Ministry of Agriculture, Forestry and Fisheries. To actualize sustainable logistics, we submitted our Declaration of Voluntary Action. We worked collaboratively with contractors in the logistics business to produce stackable boxes for truck transportation as part of our efforts toward greater loading efficiency.

We aspire to encourage all stakeholders involved in our business activities to act for CSR through these activities in collaboration with our business partners and other various stakeholders.

Status of Support for Various Declarations

Declaration of Partnership Building

Declaration of Voluntary Action for the "White Logistics" Promotion Movement