Needle Roller Bearings Thrust Bearing

Needle Roller Bearings Thrust Bearing

IKO Thrust Bearings consist of precisely machined cages and rollers. They have high rigidity and high load capacity and can be used in small spaces. Thrust Needle Roller Bearings use needle rollers, while Thrust Roller Bearings use cylindrical rollers. Various types of raceway rings are available, and can be selected according to the operating conditions. When the bearing mounting surface of a machine is heat-treated and finished by grinding, Thrust Bearings can be used without raceway rings, making the machine more compact. They are best suited for applications where high accuracy is required at high speeds and under fluctuating heavy loads, such as the drive mechanisms for automobiles, machine tools, and high-pressure pumps.

Thrust Needle Roller Bearings

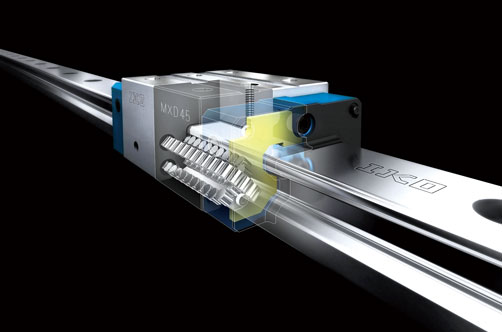

These bearings consist of a cage made from a steel plate, which is precisely press formed and surface-hardened, and needle rollers with a diameter variation within 2μm. They have a rigid structure and a high lubricant-retaining capacity. As they have the lowest sectional height compared with other thrust bearings, they can be used instead of conventional thrust washers and can withstand high-speed rotations with a low coefficient of friction.

Thrust Roller Bearings

In this series, the caged cylindrical rollers, AZK, and the complete bearings, AZ, in which AZK are combined with an inner ring (WS) and an outer ring (GS) are available. The cage has a special precise structure which is highly rigid. The cylindrical rollers are outwardly arranged and guided by the cage with exact precision to enable them to withstand heavy loads, even at high rotation speeds.