Search by Industrial Fields Machine Tools

Search for Products

Search for Products

Search Tips

Machine tools manufacture parts out of metal and other materials with high precision and efficiency. Since all machines and their parts are made by machine tools, they are also called "mother machines". The performance of mother machines has a major impact on the quality and competitiveness of products.

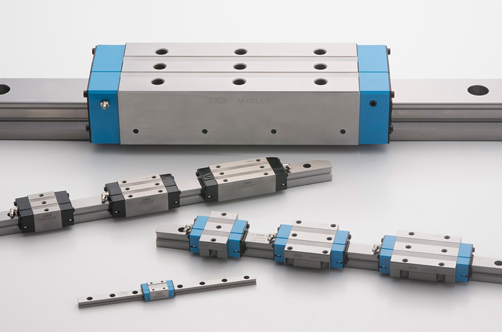

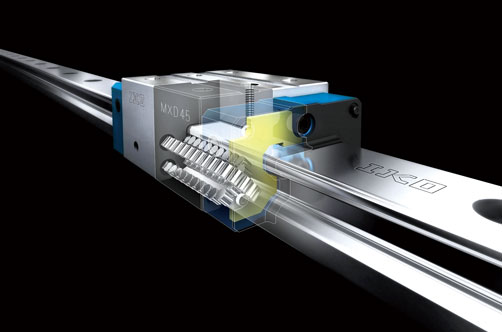

Machine tools can be divided into two basic groups: general purpose machine tools operated by workers, and NC machine tools that operate automatically using computers and numerical controls. Currently, NC machine tools account for more than 90% of the machine tool production in Japan. In particular, manufacturing sites use machining centers with automatic tool change capabilities that independently perform various types of machining according to the application. In recent years, 5-axis machining centers with 3 axes of length, width and height plus 2 axes for rotary motion have become available, enabling more complex machining. For linear motion rolling guides, high speed, high rigidity and high precision are required in order to handle the technical evolution of these machines.

Machine Tools

High-Precision 3D Compact Machining

High-precision 3D compact machining centers perform machining with high accuracy and compactness. They are used at a wide range of production sites in various industries. In recent years, higher machining accuracy and shorter machining time has become necessary. In order to meet the needs of machining technology, linear motion rolling guides must be compact and provide low running deflection and excellent vibration damping performance, as well as high load capacity and rigidity.

5-Axis, High-Precision 3D Machining

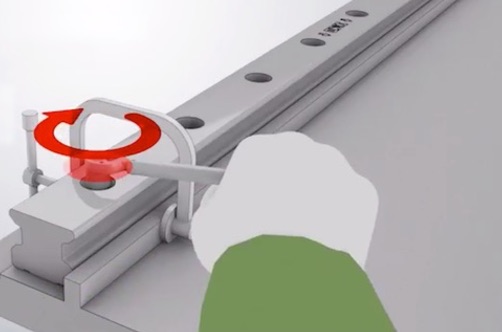

5-axis, high-precision 3D machining centers have two pivot axes in addition to X, Y and Z axes so they can handle complex and high-precision machining. An automatic work piece exchanging device is a mechanism that can automatically load and unload work pieces, performing this operation for an extended period of time. In order to achieve more complex and highly accurate machining, the linear motion rolling guide is required to have high rigidity and accuracy, and a reduced maintenance schedule.