Search by Industrial Fields Injection Molding Machines

Search for Products

Search for Products

Search Tips

Injection molding is a machining method in which materials such as plastics are heated, melted and then poured into molds. Since this process is efficient at manufacturing parts from simple to complex in large quantities and for many industries, it is used to make electronic parts, mobile phone parts, optical discs, medical equipment, PET bottles as well as everyday necessities.

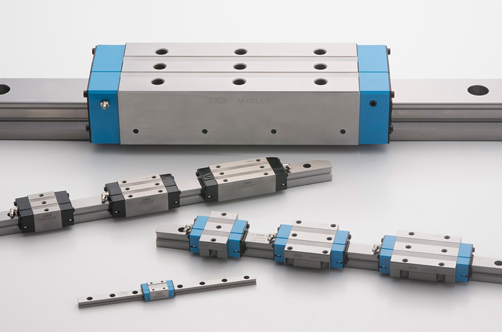

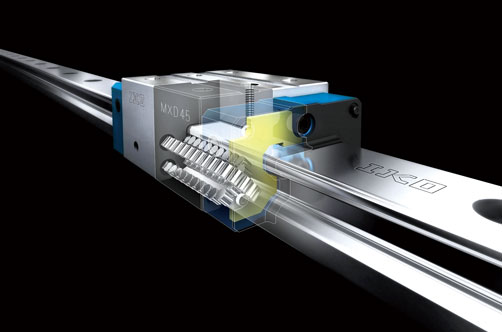

Injection molding machines include an electric type (using servo motors), a hydraulic type (using hydraulic motors), and a hybrid type (combining servo motors and hydraulic motors). The electric type has become increasingly more in demand because it can be used in clean rooms and it is energy efficient. In electric injection molding machines, even higher reliability is required, and a linear motion rolling guide with high load capacity is an essential part of the mechanical drive section.

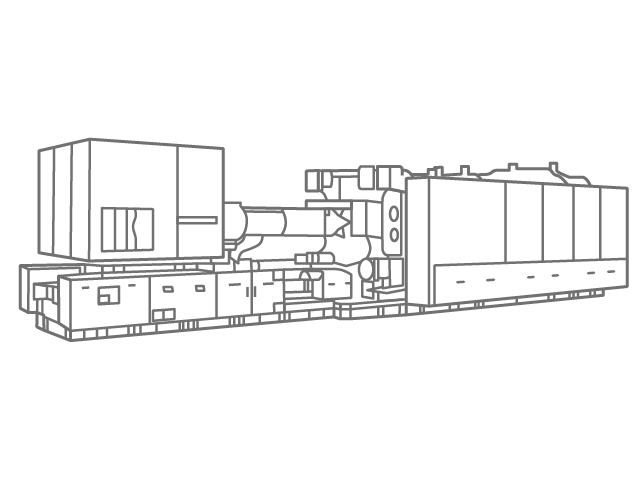

Injection Molding Machines

All-Electric Injection Molding Machine

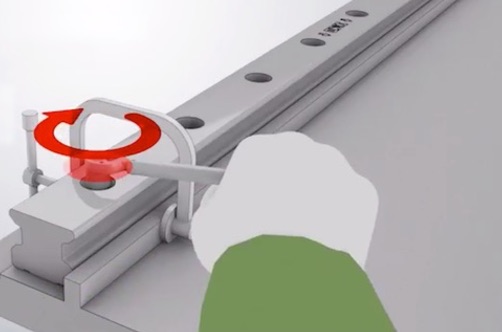

The all-electric injection molding machine consists of an injection part which melts the material and feeds it inside the mold and a mold clamping device that sets the mold. Since the mold clamping device presses the mold so that it does not open at the high pressure applied during injection, a heavy load is generated. Therefore, high load capacity is required for the linear motion rolling guide. Also, since the high operating rate requires increased productivity, reduction of maintenance steps is also important.