Linear Motion Rolling Guides Crossed Roller Way Series

Linear Motion Rolling Guides Crossed Roller Way Series

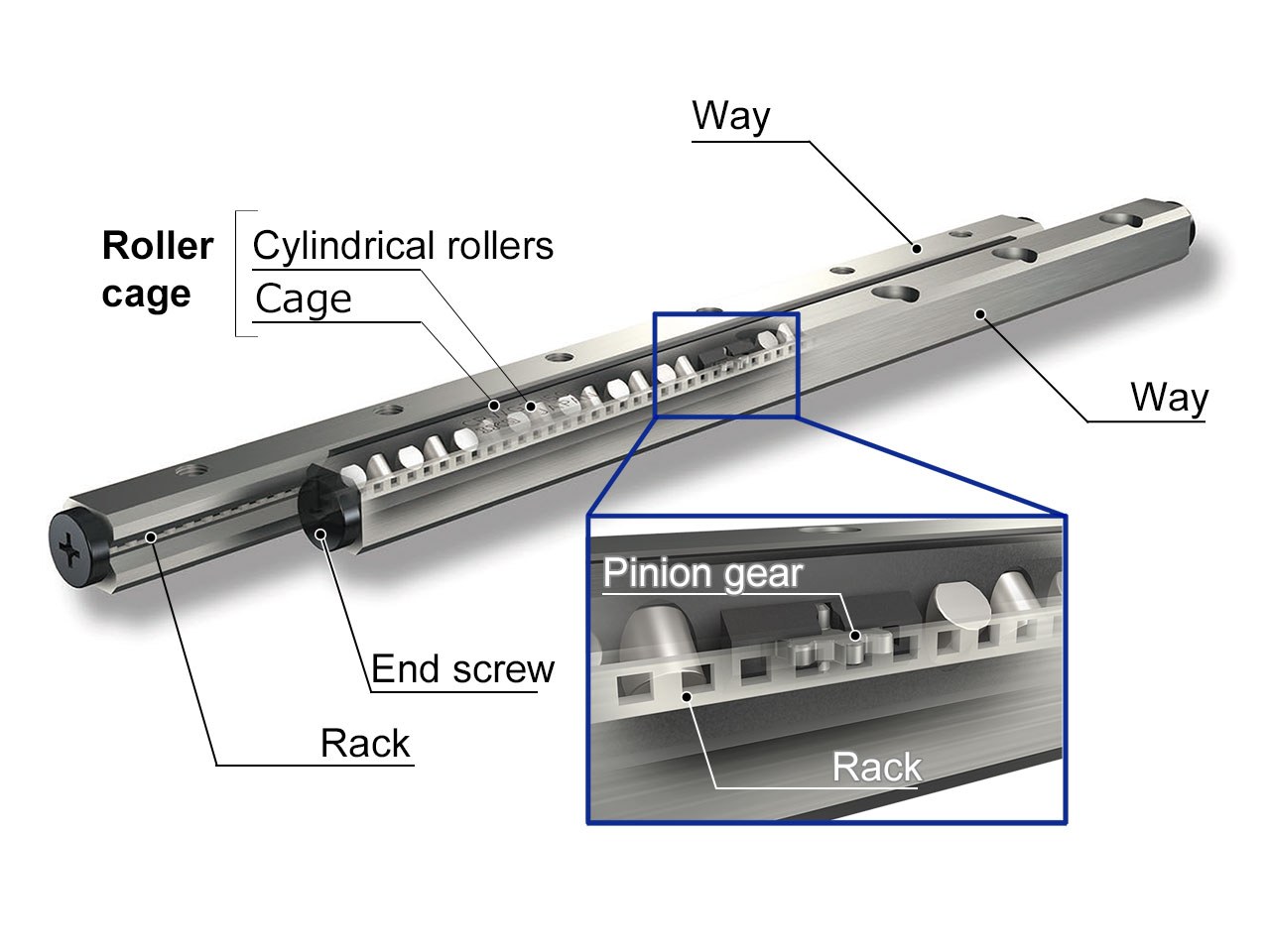

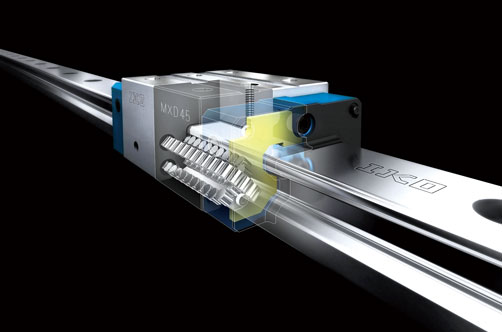

The IKO Crossed Roller Way is a linear motion rolling guide that incorporates a roller cage between two linear ways with V-shaped surfaces that act as track grooves. Because the cylindrical rollers are alternately crossed, this arrangement can handle loads in any direction while providing extremely high-accuracy and smooth linear motion. Models are available in various sizes which can be selected based on the application.

Anti-Creep Cage Crossed Roller Way

The Anti-Creep Cage Crossed Roller Way prevents cage creep by using a rack and pinion mechanism in the crossed roller way while also providing smooth linear motion with super high accuracy.

Solves Cage Creep Issue

The built-in rack and pinion mechanism is the perfect solution for cage creep. It provides reliable operation in various situations where a crossed roller way may have issues, including applications on a vertical axis. No correction for cage creep is necessary, even under high velocity or long term operation.

Interchangeable Mounting Dimensions

Since the rack is placed inside the way, it maintains the same outside dimensions. This provides complete mounting compatibility with the conventional crossed roller way, making it easy to replace the conventional type in machines and equipment, as well as using it in new designs.

Anti-Creep Cage Crossed Roller Way H

The Anti-Creep Cage Crossed Roller Way H eliminates cage creep by using a rack and pinion mechanism in the crossed roller way while enabling smooth linear motion with super high accuracy. The load rating on CRWG-H is significantly higher because the length of the contact points with the raceway and the number of cylindrical rollers is increased. The outer dimensions and shape are the same as the conventional CRWG.

Improved Load Capacity and Rigidity

CRWG-H has a higher load rating compared to the conventional type because the lengthe of the contact points with the raceway have been increased.

Solves Cage Creep Issue

The built-in rack and pinion mechanism prevents cage creep issues..

Interchangeable Mounting Dimensions

Since the rack is placed inside the way, it has the same mounting dimensions as the conventional crossed roller way, making replacement easy.

Crossed Roller Way

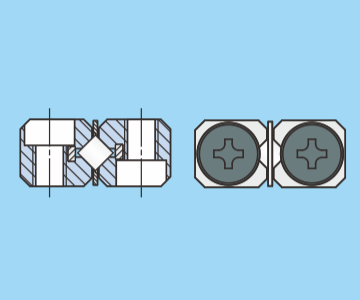

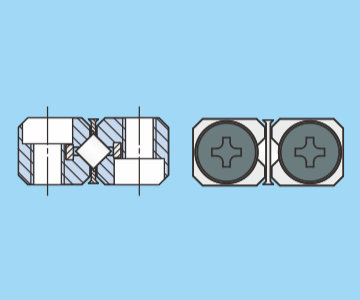

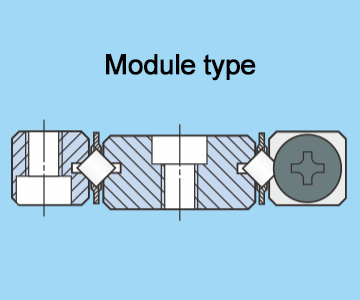

Standard Type and Module Type

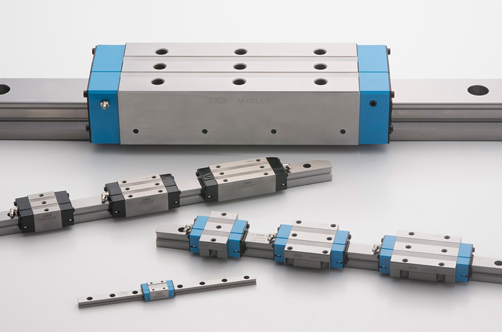

Models include the standard type, which combines four ways and two roller cages, and the module type that has an integrated structure containing two ways.

Smooth Motion

A highly accurate raceway surface and precision cylindrical rollers that are the precise length are incorporated in the cage in order to reduce skew, resulting in linear motion with very small, smooth friction resistance without stick-slip.

High-Carbon Chromium Bearing Steel and Stainless Steel Types

The standard type is available in either high-carbon chromium bearing steel or stainless steel.

Easy Mounting

Since the mounting hole of the way is counter bored and female-threaded, the way can be fixed to the equipment with either a female thread or a bolt that is passed through from the equipment, allowing for flexible mounting options. The module type has two internal ways integrated in a single component and a simple mounting structure that eliminates machining errors, enabling high accuracy linear motion.

Line-Up

Crossed Roller Way

| Product | Material | Shape | Model | Size | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 6 | 9 | 12 | 15 | 18 | 24 | ||||

| Anti-Creep Cage Crossed Roller Way | High carbon steel made |

|

CRWG | - | ○ | ○ | ○ | ○ | - | - | - | - | - |

| Anti-Creep Cage Crossed Roller Way H | High carbon steel made |

|

CRWG…H | ○ | ○ | ○ | ○ | - | - | - | - | - | - |

| Crossed Roller Way | High carbon steel made |

|

CRW | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Crossed Roller Way | Stainless steel made | CRW…SL | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | |

| Crossed Roller Way | High carbon steel made |

|

CRWM | ○ | ○ | ○ | ○ | - | - | - | - | - | - |

Special Specifications

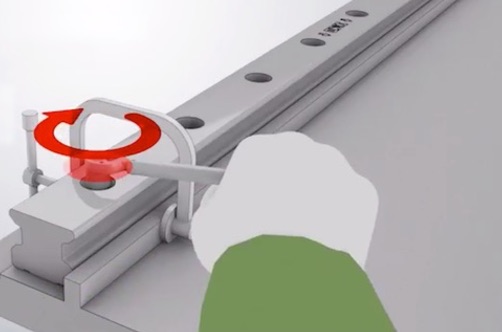

Special mounting crew

Preload adjusting-side way can be moved by adjusting the preload. Allowance for movement is required between a way fixing screw and mounting hole, but special mounting screws are provided for the cases where enough allowance is not provided or a fixing screw should be mounted from the way side. This special mounting screw can also be used for the case where the mounting hole for mounting the fixed-side way and positioning accuracy of female thread are not enough. This special mounting screw is high carbon steel-made only.

Wiper seal

In order to prevent foreign substances from entering into a raceway, the wiper seal is changed into the one with a function of end stopper SB. The wiper seal cannot be mounted on all way ends. The mounting positions can be changed by loosening the screw.

High rigidity roller cage

The cage is changed into a high rigidity copper alloy-made cage designed to suit vertical axis application. This cage has a structure to prevent a roller from dropping off in one-side direction. For using a high rigidity roller cage for vertical axis application, it is recommended to use the cage in combination with end stopper SB.

End stopper SA

When the stroke frequency is high and cage creep may be caused by the vibration and non-uniformly varying load, the end screw is changed into end stopper SA. For the series of size 1, an end stopper SA according to end stopper SA is included as standard.

End stopper SB

When using a high rigidity roller cage for vertical axis application, the end screw is changed into end stopper SB to regulate the cage stroke at the end. The end stopper SB cannot be mounted on all way ends. The mounting positions can be changed by loosening the screw.