製品情報 メカトロシリーズ

製品を探す Search for products

製品を探すSearch for products

検索のヒント

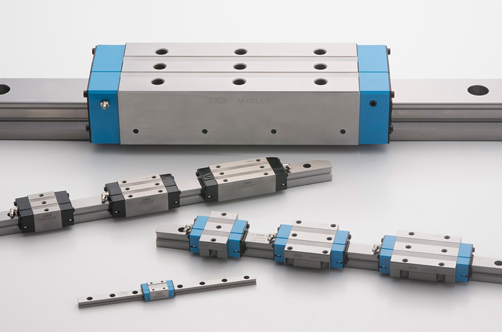

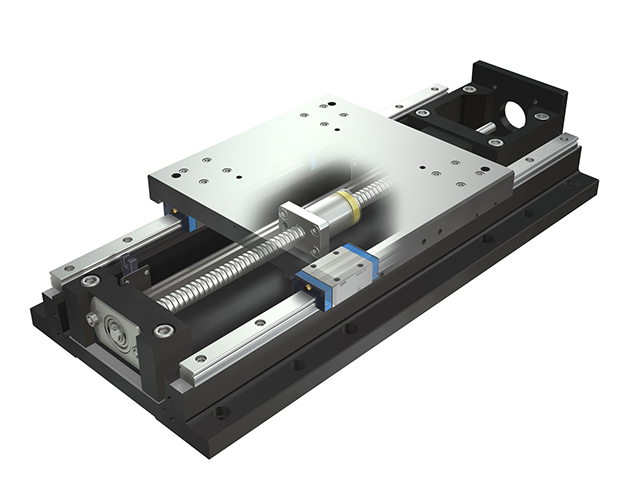

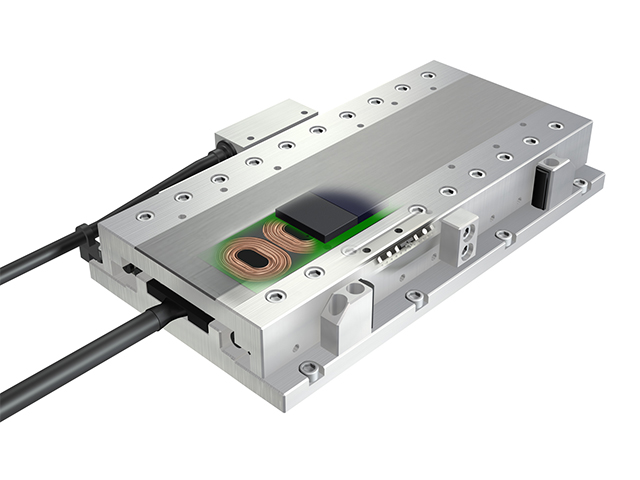

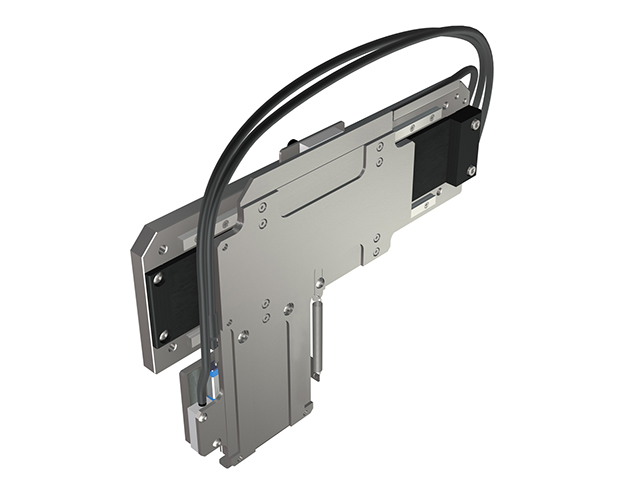

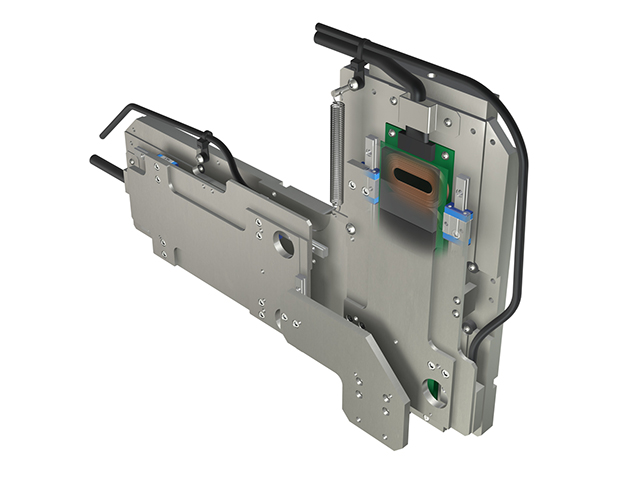

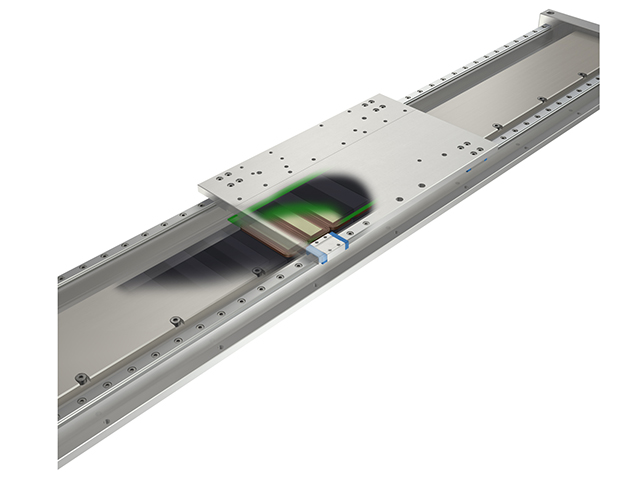

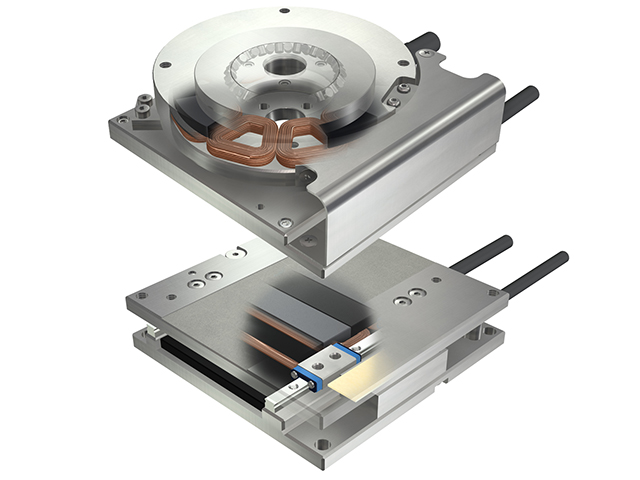

メカトロシリーズは、精密加工技術とエレクトロニクスの融合により生まれた製品です。ベッドとスライドテーブルの間に直動シリーズとボールねじやモータを組み込んだ精密位置決めテーブルは、モジュールタイプから高精密タイプまでを幅広くラインナップ。半導体製造装置やフラットパネルディスプレイ製造装置、各種精密機器などの位置決め機構として、幅広い分野で活躍しています。位置決めテーブルや制御用の電装装置まで一括して提供することにより、設計・組立工数などの削減に貢献しています。

-

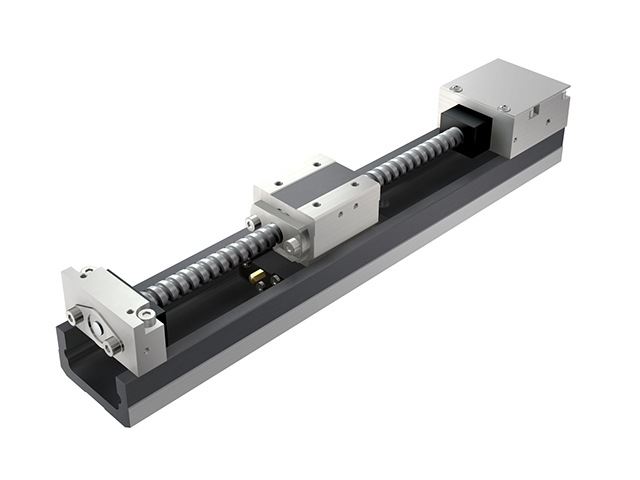

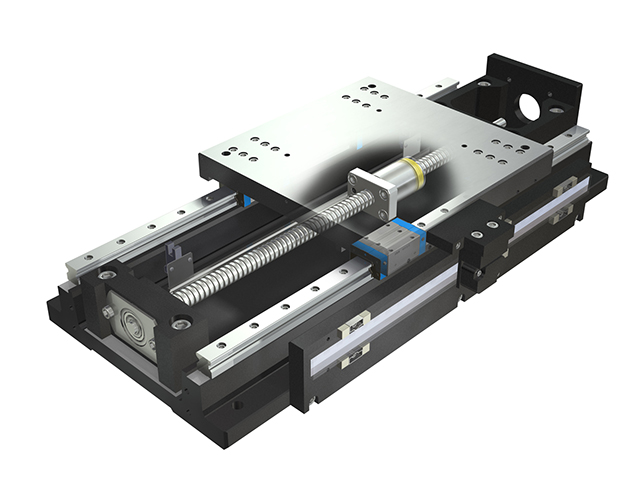

ボールねじ駆動タイプ 精密位置決めテーブルTU

-

ボールねじ駆動タイプ 精密位置決めテーブルTE

-

ボールねじ駆動タイプ クリーン精密位置決めテーブルTC

-

ボールねじ駆動タイプ マイクロ精密位置決めテーブルTM

-

ボールねじ駆動タイプ 精密位置決めテーブルTS・CT

-

ボールねじ駆動タイプ 精密位置決めテーブルL

-

ボールねじ駆動タイプ 精密位置決めテーブルLH

-

ボールねじ駆動タイプ 高精密位置決めテーブルTX

-

ボールねじ駆動タイプ アライメントテーブルAT

-

ボールねじ駆動タイプ アライメントモジュールAM

-

ボールねじ駆動タイプ パラレルドライブステージ™PD・・・S

-

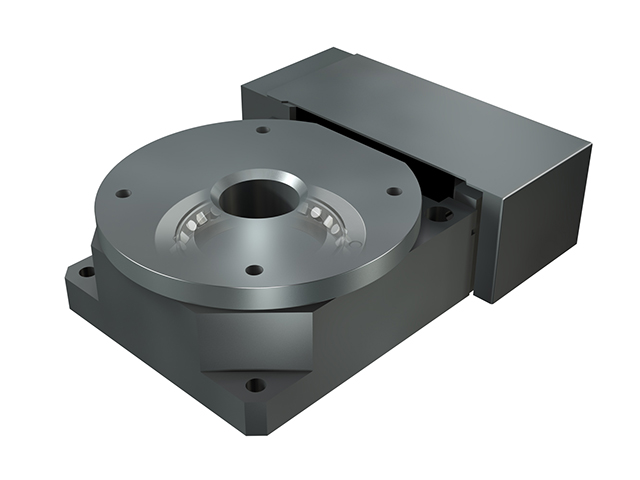

ウォームギア駆動タイプ 回転ステージSK・・・W

-

ボールねじ駆動タイプ 精密昇降テーブルTZ

-

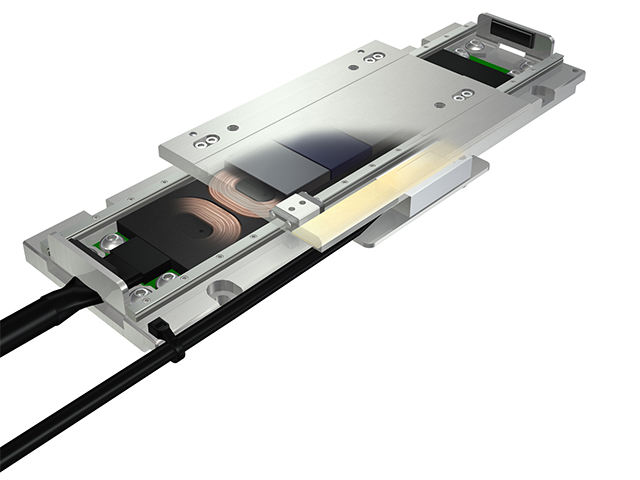

リニアモータ駆動タイプ ナノリニア®NT・・・V

-

リニアモータ駆動タイプ ナノリニア®NT・・・H

-

リニアモータ駆動タイプ ナノリニア®NT・・・XZ

-

リニアモータ駆動タイプ ナノリニア®NT・・・XZH

-

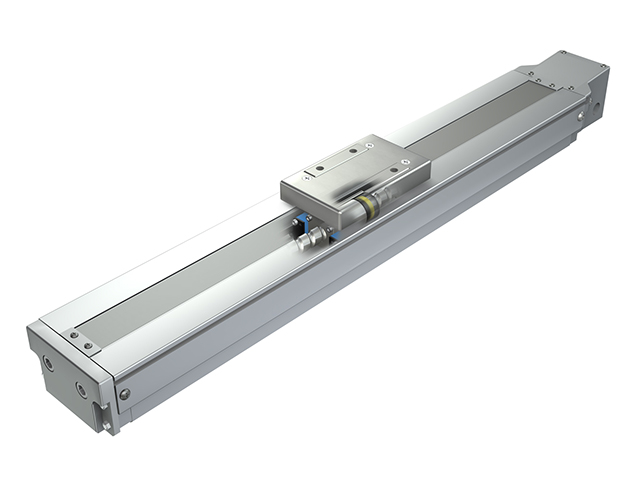

リニアモータ駆動タイプ リニアモータテーブルLT

-

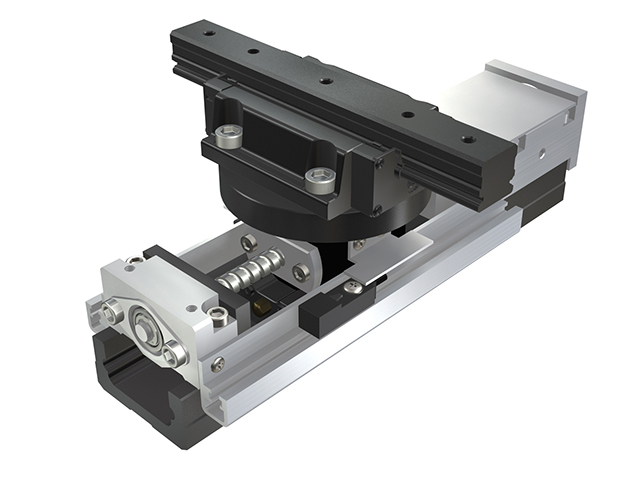

リニアモータ駆動タイプ アライメントステージSA

-

タイミングベルト駆動タイプ 精密位置決めテーブルLB