Needle Roller Bearings Super Slim Type Crossed Roller Bearings

Needle Roller Bearings Super Slim Type Crossed Roller Bearings

Super Slim Type Crossed Roller Bearings are extremely compact bearings with 5.5 mm sectional height and 5 mm width. Separators are incorporated between cylindrical rollers for smooth rotation. Contributes to making machines or equipment more compact and lightweight.

Features

The cross sectional height is reduced by 69% in comparison with the Slim Type Crossed Roller Bearing CRBS, previously the slimmest. The width is also as small as 5 mm and the cross sectional area is reduced by 43% in comparison with conventional products. Also, the mass ratio is 0.38, realizing significant weight saving in comparison with CRBS. (compared with a product with bearing bore diameter of 50 mm)

Product Overview

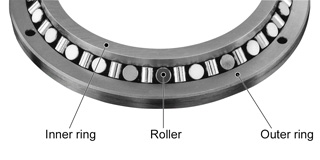

What are Crossed Roller Bearings?

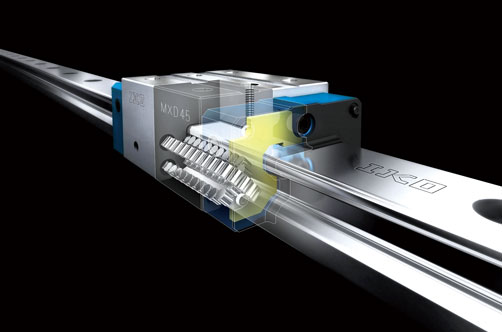

Crossed Roller Bearings are compact bearings with their rollers alternately crossed at right angles to each other between inner and outer rings. The orthogonal array of rollers allows the bearing to handle complex loads simultaneously from any direction, which makes assembly possible without needing to worry about load direction.

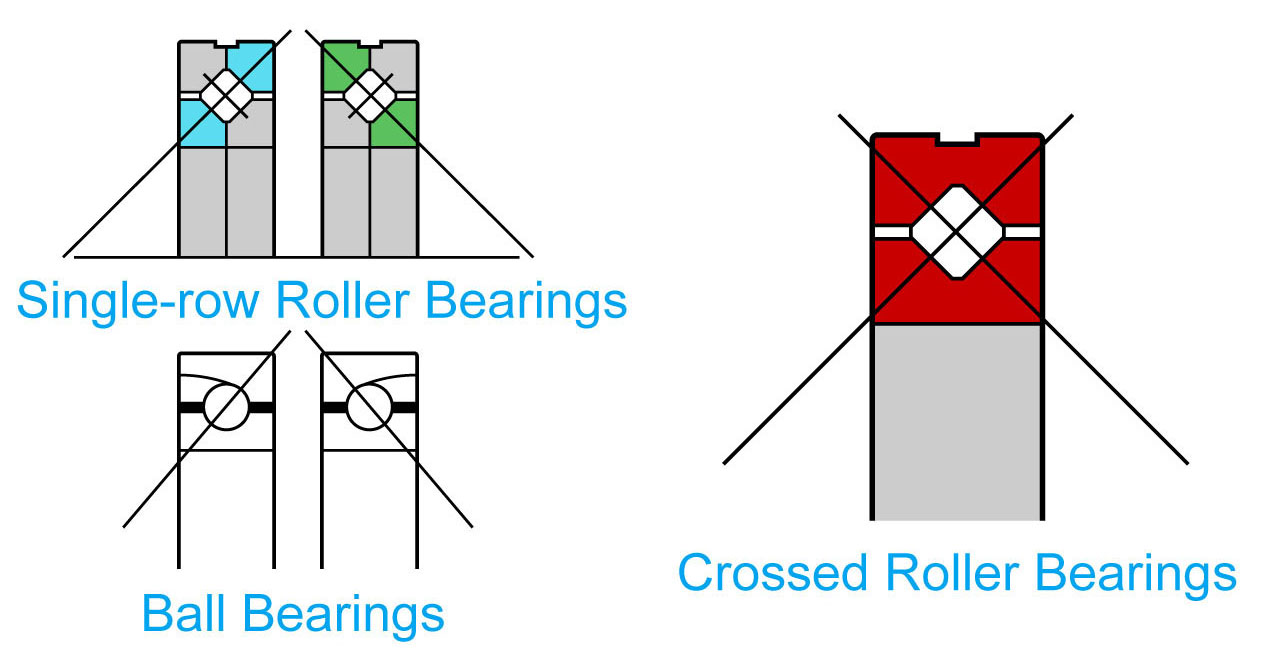

Compact

The orthogonal array of rollers reduces the cross sectional area of rear-mounted 45° contact angle roller bearings or single row ball bearings by half. This compact design allows you to more effectively utilize space in your application.

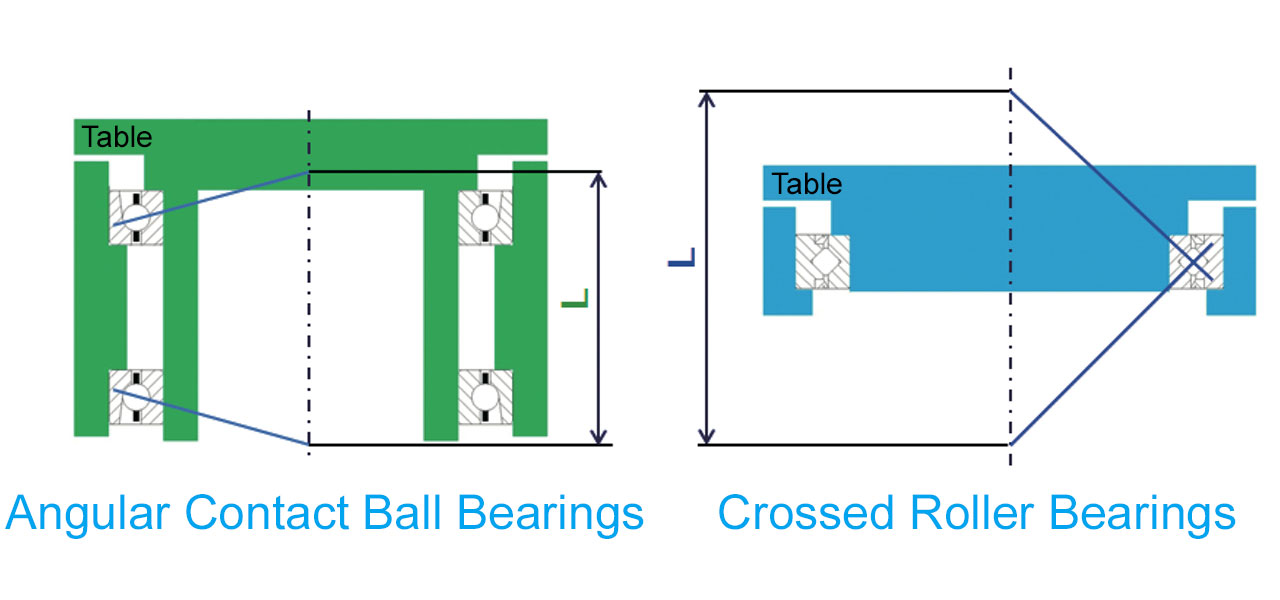

High Rigidity

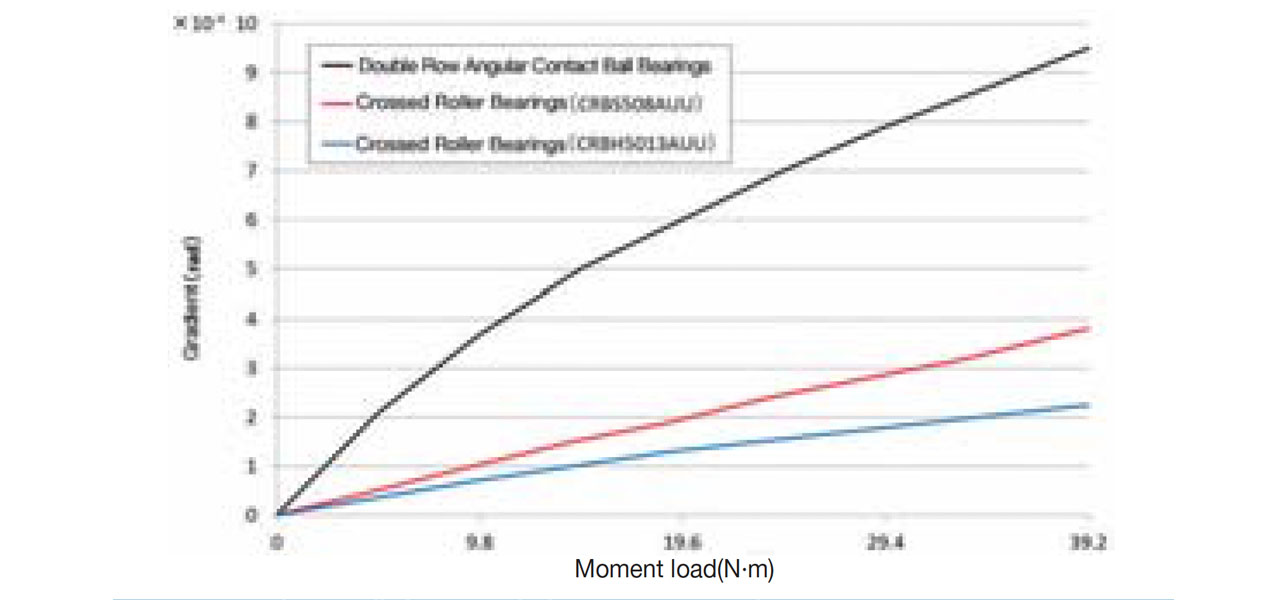

The figure is a cross-section of a rotating turntable. The application point distance from the time moment load is applied to the turntable is L, and the allowable moment load of the bearing is proportional to application point distance L. If increasing application point distance L to increase the moment rigidity of the turntable, two Angular Contact Ball Bearings are required. Because of the need for distance between the bearings, the equipment size increases as well. However, even a single Crossed Roller Bearing can increase application point distance L, keeping equipment compact and improving moment rigidity.

Because of the line contact structure, when using rollers for the bearing inner rolling elements, rigidity is greatly improved compared to ball type bearings. For example, rigidity is increased 3 to 4 times while achieving more compact cross-section dimensions compared to a double row Angular Contact Ball Bearing.