IKO Technology Special Environments

IKO will open up a new world of products for special environments by utilizing IKO's particular ideas and experiences.

IKO products are used in a broad range of fields such as industrial robots, machine tools, and semiconductor manufacturing equipment. Their usage environment becomes diversified every year. In order to meet the respective needs, we are developing and supplying products which incorporate our own ideas and experience.

Clean

○stainless linear Way and Linear Roller Way

●Black chrome surface treatment

●Specified grease(CG2 or CGL grease)

◇Fluorine grease

Corrosion resistance

○Non-magnetic stainless Linear Roller Way Super X

○Stainless Linear Way and Linear Roller Way

○Hybrid C-Lube Linear Way ML

●Black chrome surface treatment

Vacuum

●No end seal

●Stainless steel end plate

◇Fluorine grease

Heat Resistance

●Stainless steel end plate

●Special environment seal

◇High temperature grease

Foreign Substances (wood chips and metal powder, etc.)

○Linear Way H Ultra seal specification

○Track rail mounting from bottom

●Double end seals

●Scrapers

●C-Wiper

●Rail cover sheet

●Caps for rail mounting holes

●Rail cover plate for track rail

●Female threads for bellows

●Specific bellows

Spatter

●Scrapers

●Caps for rail mounting holes (aluminum alloy)

●Rail cover sheet

●Fluorine black chrome surface treatment

●Stainless Steel End Plate

○Linear Motion Rolling Guide series for special environment:

Collective name of Linear Motion Rolling Guide series models corresponding to special environment.

●Special specification for special environment:

Special specification corresponding to special environment by combination of Linear Motion Rolling Guide series.

◇Lubricant:

Lubricant suitable for each special environment can be selected.

Products for Special Environments

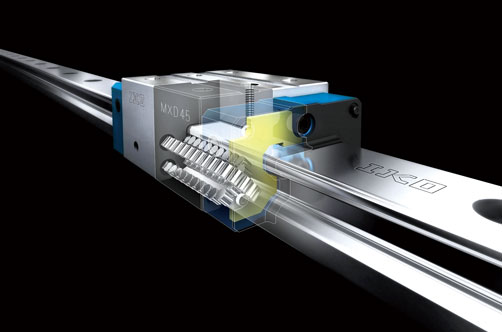

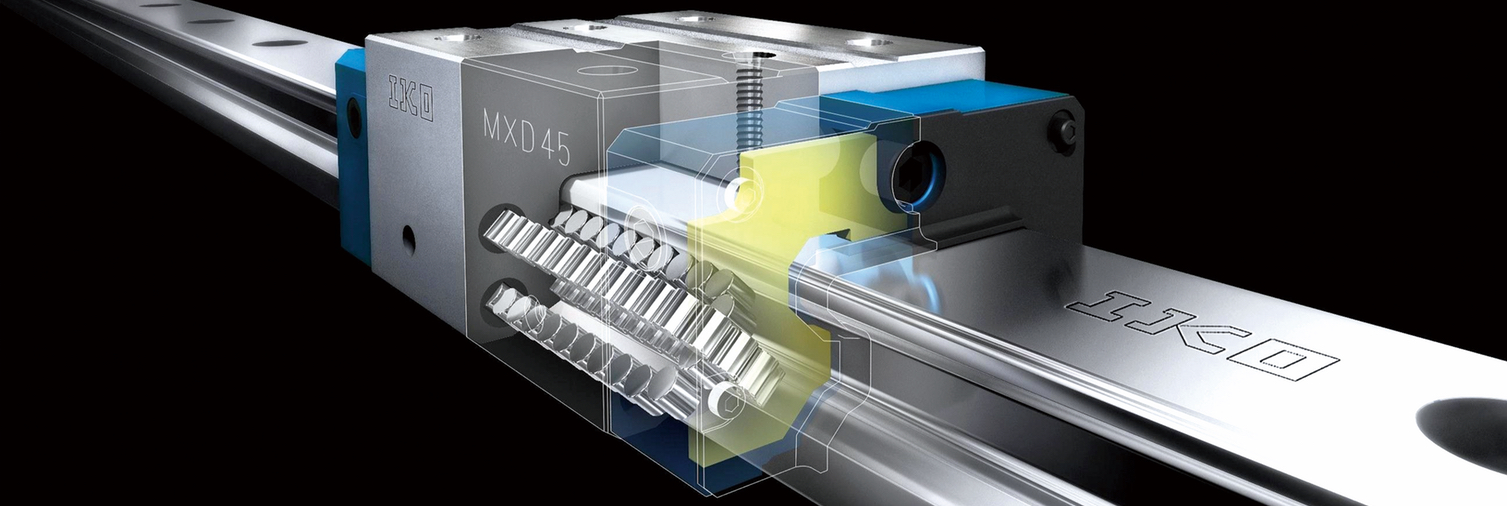

Products for Special Environments Hybrid C-Lube Linear Way ML

While maintenance free performance of C-Lube Linear Way ML is maintained, the silicon nitride ceramics ball improves high-speed performance and reduces noise level. Ceramics has more resistance to deformation and more rigidity than bearing steel and stainless steel.

1.Superior high-speed performance

2.Noise reduction

3.High rigidity

4.Superior abrasion resistance

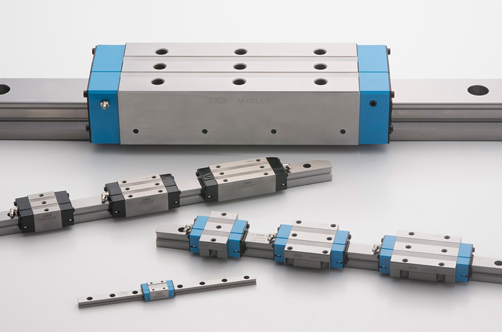

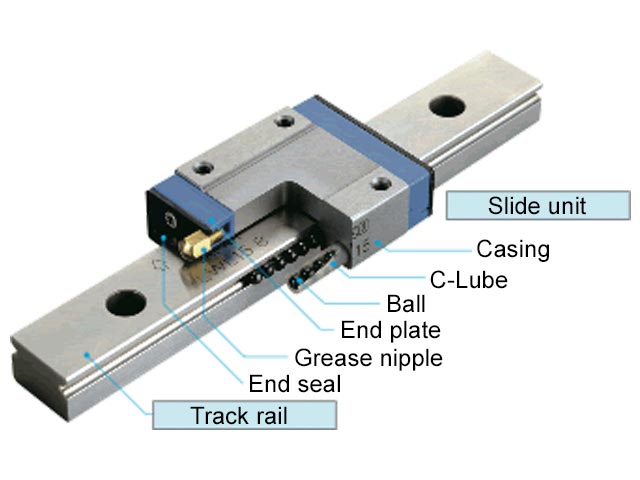

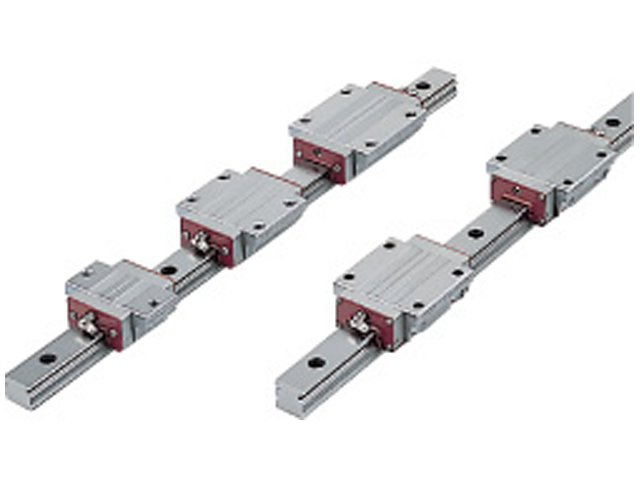

Products for special environments Stainless Linear Way and Linear Roller Way

IKO's Linear Way and Linear Roller Way lineup include products with stainless steel made parts instead of steel parts. As stainless steel is resistant to rust relative to high carbon steel made products, they are optimal for use in applications where oil and rust prevention oil are not preferred. It is also suitable for use in cleanroom environment room, so use clean grease that inhibits dust-generation amount together.

Main component materials

| Casing | Martensitic stainless steel |

|---|---|

| Track rail | Martensitic stainless steel |

| Ball | Martensitic stainless steel |

| Ball retaining band | Stainless steel |

| End plate | Engineering plastic |

| End seal | Stainless steel + Synthetic rubber |

| Grease nipple | Brass |

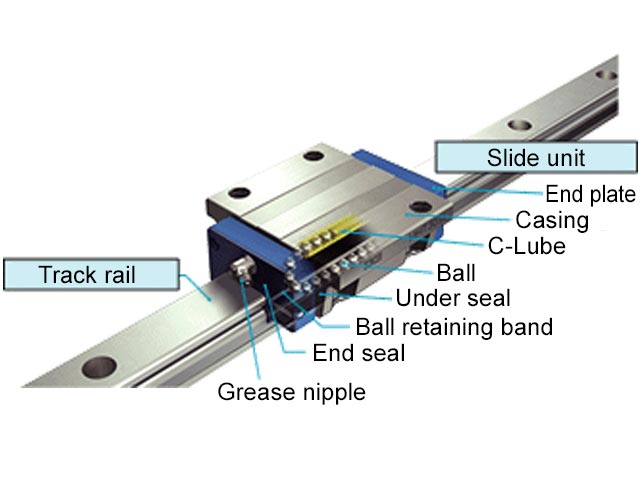

Products for special environments Non-magnetic stainless Linear Roller Way Super X

The non-magnetic stainless Linear Roller Way Super X is the world's first non-magnetic stainless steel endless motion roller type linear motion rolling guide to attain relative magnetic permeability of 1.01 or less. This is accomplished through the dedicated development of silicon nitride ceramic cylindrical rollers and non-magnetic stainless steel casings and track rails. Despite being non-magnetic material it still maintains the superior vibration characteristics, excellent running accuracy, and friction characteristics provided by the Linear Roller Way Super X. This allows for accurate and rapid positioning in environments affected by minimal magnetism.

1.World first for roller types

2.Relative magnetic permeability 1.01 or less

3.High corrosion resistance

4.High running accuracy

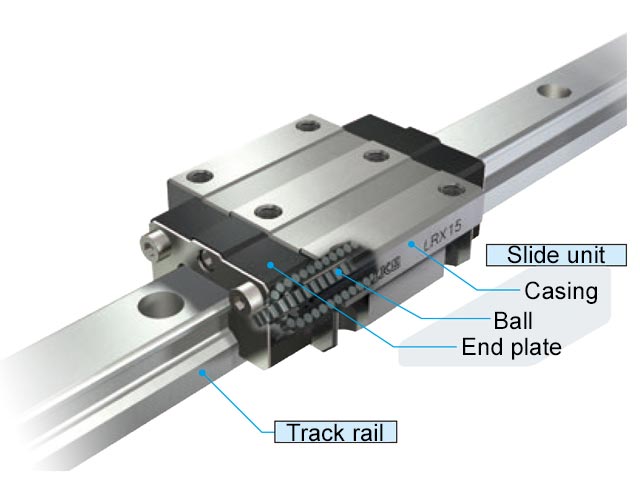

Special specification for special environment / Dust protection

IKO's Linear Way and Linear Roller Way lineup include following special specifications to correspond to various special environments.

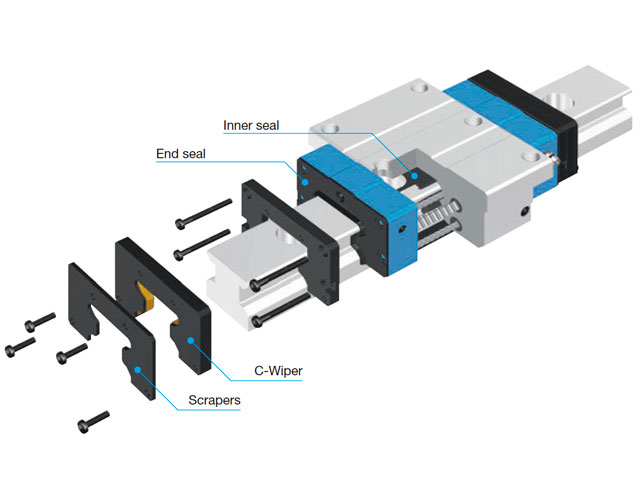

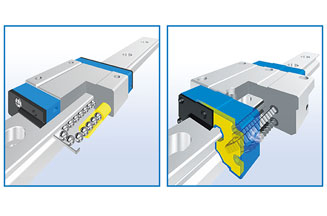

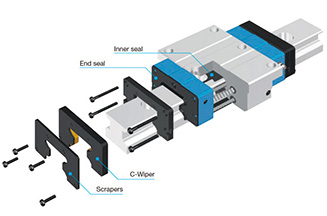

Dust protection C-Wiper /RC

Mounted to the outside of end seal, it may be used for long time even under environment where metal chips are spattering. End seal, inner seal (/UR) and scraper (/Z) may be equipped as standard when you specify special specification /RC with C-Wiper. If you need inner seal only, specify /UR.

Dust protection Rail cover sheet

Rail cover sheet that consists of steel plate and adhesive tape and fastened to the dedicated track rail with groove on the track rail prevents foreign substances from entering into the slide unit.

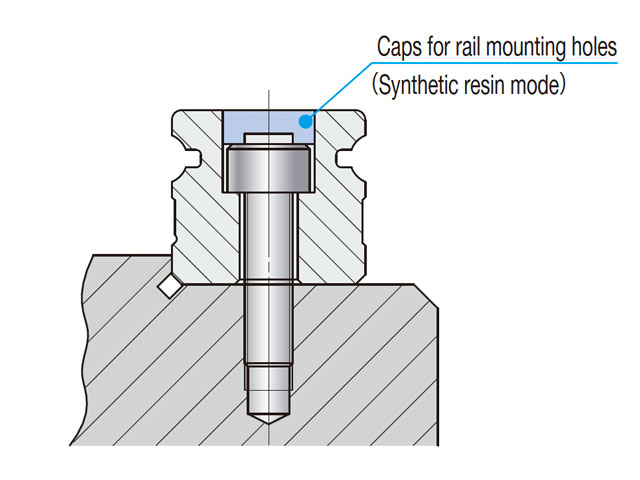

Dust protection Caps for rail mounting holes /F

Caps for rail mounting holes close the track rail mounting holes to prevent foreign substances from entering into the slide unit. Contact IKO for aluminum alloy caps for rail mounting holes.

Dust protection Rail cover plate /PS

Rail cover plate totally covers the upper surface of the track rail to prevent foreign substances from entering into the track rail.

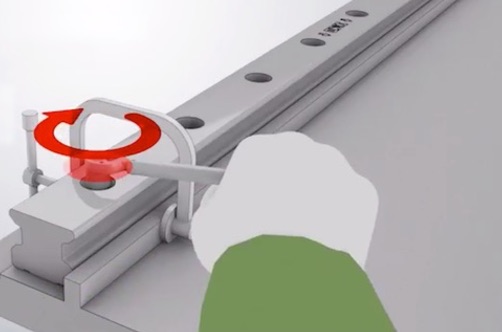

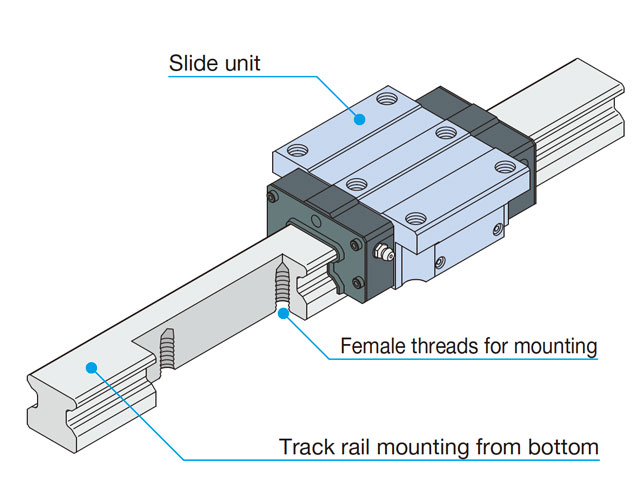

Dust protection Track rail mounting from bottom

This is the specification that track rail is fixed from the mounting surface side. As there are no mounting holes on the track rail upper surface, adherence with the seal is superior and better dust protection effect is achieved.

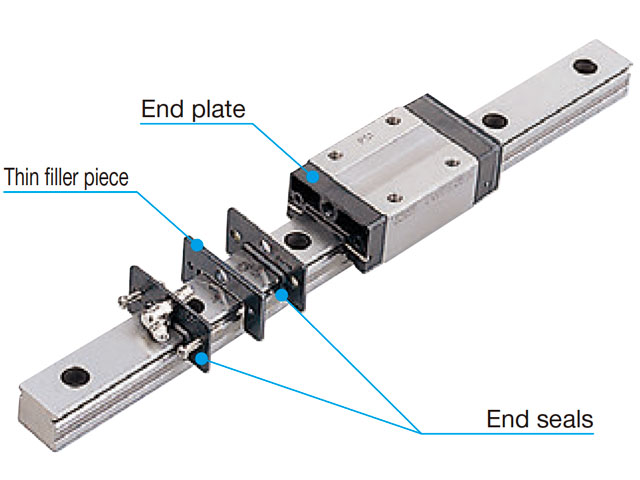

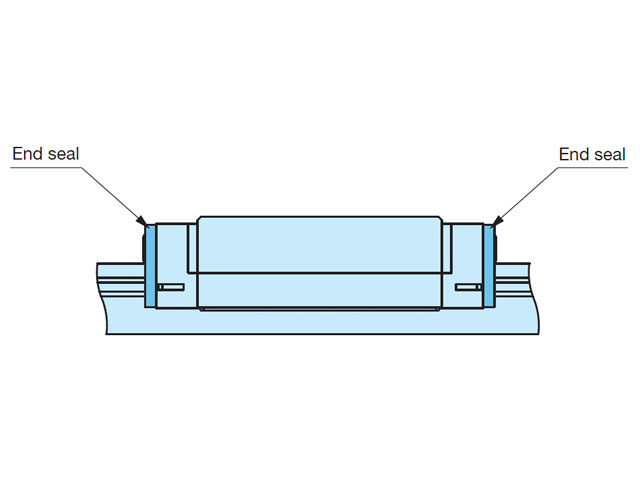

Dust protection Double end seals /V

Double end seals improve the dust protection property further.

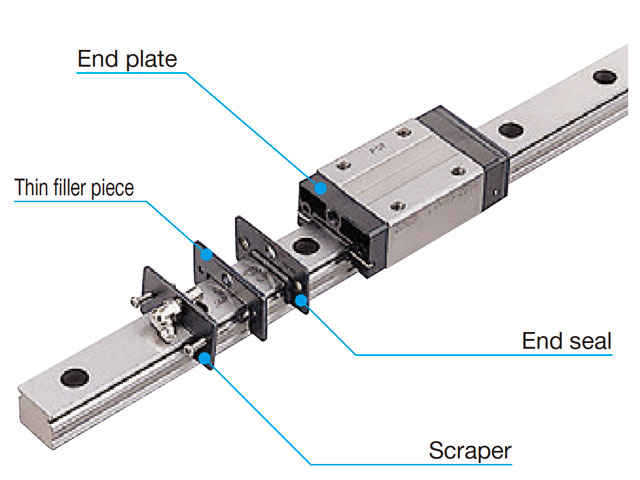

Dust protection Scraper /Z

Mounted to the outside of end seal, it may remove large foreign substances adhering to the track rail.

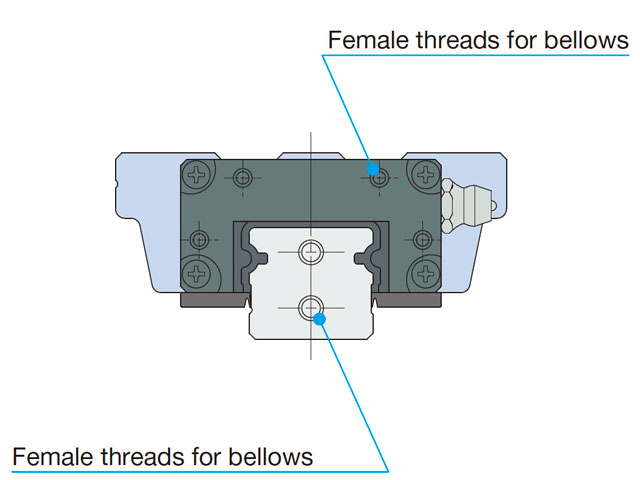

Dust protection Female threads for bellows/J

Female threads for bellows are prepared on the slide unit and track rail ends.

Dust protection Specific bellows

Dust protection cover over the exposed part of the track rail.

Dust protection End seal /US

Attach end seals instead of scrapers on both sides of the slide unit in order to improve the dust protection performance.

* Applicable to MLV series. (End seals are mounted as standard to other Linear Ways and Linear Roller Ways.)

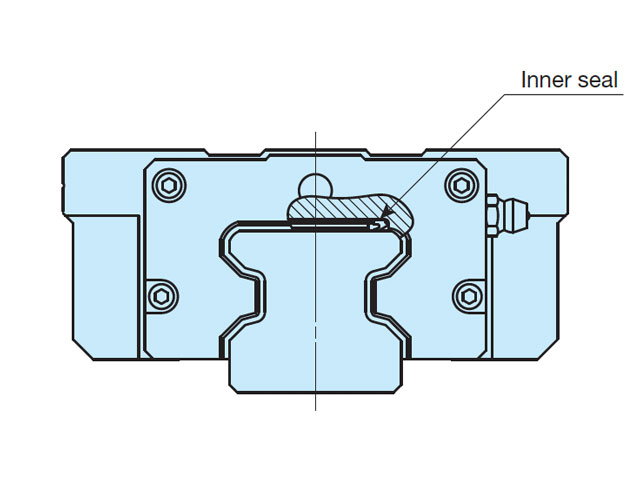

Dust protection Inner seal /UR

Attach the inner seal to the inside of the slide unit. Inner seal improves dust protection property of the cylindrical roller circulation part against foreign substances from the upper surface of the track rail.

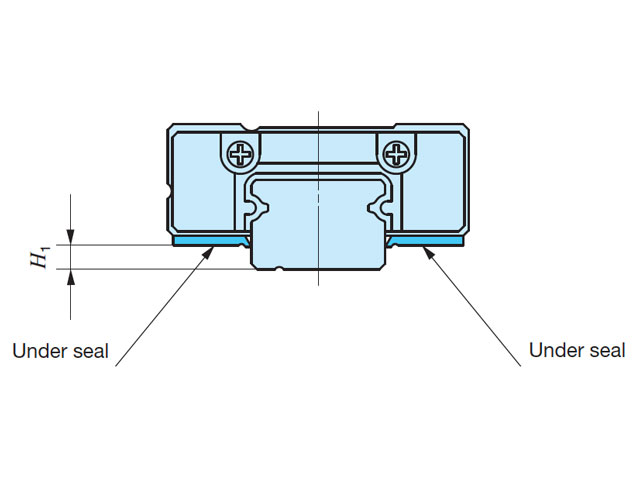

Dust protection Under seal /U

The seal is attached to the bottom of the slide unit to prevent foreign substances from entering from underneath.

Note: For C-Lube Linear Way UL and Linear Way U, attach "upper seal". The seal is attached to the upper end of the slide unit to prevent foreign substances from entering from above.

Special specification for special environment / Lubrication

Lubrication With C-Lube plate /Q

Lubrication parts to substantially reduce the need for lubrication management, i.e. grease job.

Lubrication Low Dust-Generation Grease for Clean Environment CGL /YCL

For this grease, mixed soap is used as thickener and synthetic oil and low pour point mineral oil are mixed with base oil, so it has excellent low dust generating performance, rolling resistance, lubrication, and rust prevention property.

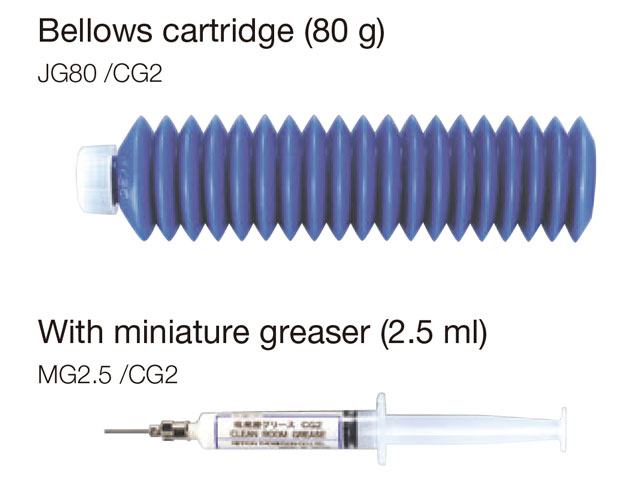

Lubrication Low Dust-Generation Grease for Clean Environment CG2 /YCG

For this grease, urea is used as thickener and synthetic oil is used as base oil, so it has excellent low dust generating performance, operating temperature range, lubrication property, rust prevention property and oxidation stability.

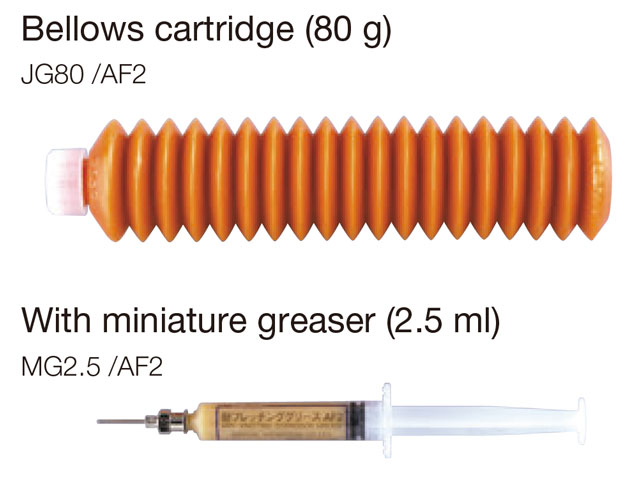

Lubrication Anti-Fretting Corrosion Grease AF2 /YAF

Grease with excellent fretting-proof corrosion property.

Lubrication Other special grease

If you need any special grease for vacuum or high temperature, ask IKO for your request.

Special specification for special environment / Corrosion resistance

Corrosion resistance Black chrome surface treatment /L

Acrylate resin coating is applied to improve the rust prevention property after black impregnated chrome surface treatment.

Corrosion resistance Fluorine black chrome surface treatment/LF

Fluorinated resin coating is applied to improve the rust prevention property after black impregnated chrome surface treatment. In addition, this prevent foreign substances from sticking to the surface.

For special environments Special Specifications / Others

Others Stainless steel end plate /BS

Stainless steel end plate /BS

Others Special environment seal /RE

The end and under seals are replaced with end seals for special environment that can be used at high temperatures. When it is used in high temperature environment, stainless steel end plate (/BS) and high temperature grease should be combined.

The photo shoes a combination of special environment seal (/RE) and stainless steel end plate (/BS).

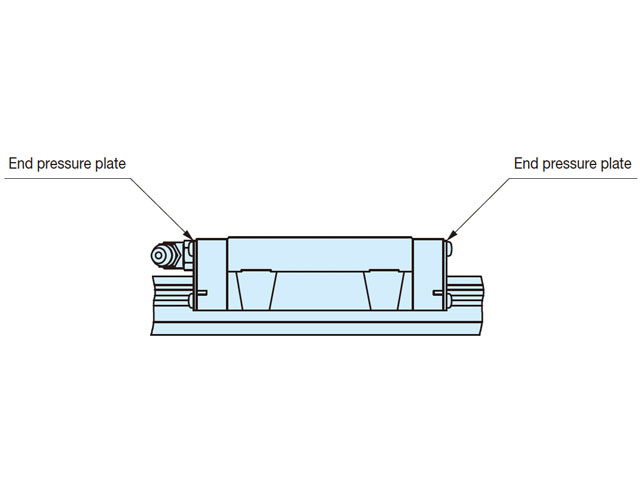

Others No end seal /N

End seals at both ends of the slide unit can be replaced with end pressure plates, which do not come in contact with the track rail, to reduce frictional resistance. No under seal is attached. This specification is not effective for dust protection.

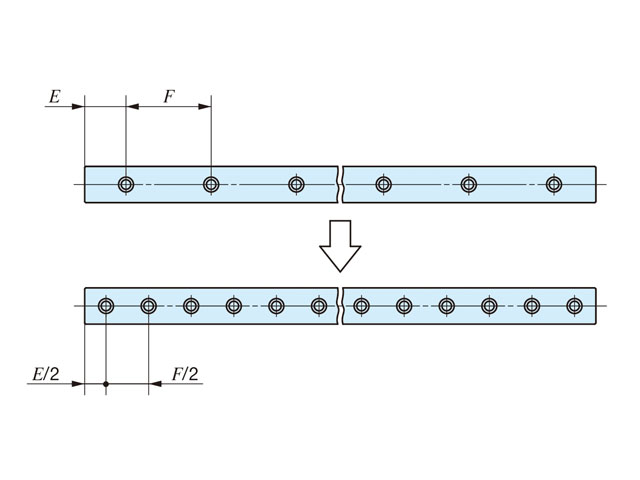

Others Half pitch mounting holes for track rail /HP

Set the pitch of track rail mounting holes to a half of the standard F dimension. The specification with bolts for track rail mounting holes are supplied with the required number of bolts.

High quality, high performance products manufactured by IKO.

Introducing IKO original technologies,"ALL IKO's own."

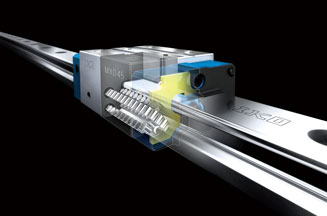

Capillary Technology

"C-Lube," IKO's original lubricating part, using the capillary action (capillarity). "C-Lube" can minimize the quantity of required lubricant and realize maintenance-free products. "C-Lube" can greatly contribute to the environment of the earth.

Interchange Specification

Due to IKO's unique and high machining technology and strict dimensional management of slide units and track rails, unparalleled highly interchangeable products can be realized. You can order whatever you want, whenever you want, and as much as you want.

Small Sizing

Simple structure and compact design based on proprietary down-sizing technology. Even in case of extremely small size products, high performance and high quality are realized.

Roller Technology

In comparison with ball bearings, rollers have minimal elastic deformations in terms of load. Taking full advantage of these characteristics, smooth operation, high reliability, high rigidity, and high accuracy were realized.

Extra Long Unit

IKO have greatly improved the load capacity and run-outs of the long unit by extending conventional long units without changing the sectional dimensions. This can downsize the guide mechanism and improve the performance without re-designing the units.

Special Environments

With IKO's special ideas and experiences, IKO have lineups of various products for special environments. You can select products fit for your requirement.